Manuscript accepted on : 09 -01- 2021

Published online on: 19-01-2021

Plagiarism Check: Yes

Reviewed by: Dr. Jagdish Joshi

Second Review by: Dr. Al-Temimi, Ammar B

Final Approval by: Dr. Majid Sakhi Jabir![]()

Paroma Arefin1*

![]() , Rezvi Ahmed2, Md Shehan Habib1

, Rezvi Ahmed2, Md Shehan Habib1 , Sreebash Chandra Bhattacharjee1, Dipankar Chakraborty1, Suman Das1, Debabrata Karmakar1

, Sreebash Chandra Bhattacharjee1, Dipankar Chakraborty1, Suman Das1, Debabrata Karmakar1 and Dip Bhowmik1

and Dip Bhowmik1

1BCSIR Laboratories, Chattogram, Bangladesh Council of Scientific and Industrial Research (BCSIR), Bangladesh.

2ASA University Bangladesh.

Corresponding Author E-mail: paroma.arefin@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/2883

ABSTRACT:

Critical Quality Attributes (CQAs) is an important factor in Pharmaceutical development as it determines the strength, release of the API from SDFs, and stability of a pharmaceutical dosage form. Moreover, substandard and counterfeit drugs have been a major concern in recent days.Ciprofloxacin is a second-generation fluoroquinolone derivative that exerts its effects by inhibiting bacterial DNA gyrase (Topoisomerase II). It is used for the treatment of bacterial gastroenteritis, respiratory tract infections, controlling bronchitis and pneumonia caused by Gram negative bacteria. Ciprofloxacin has been listed in the World Health Organization (WHO) Model list of Essential Medicines. In recent decades, the pharmaceutical industry has been experiencing excellent growth in both local and international market.In our present study, we have analyzed theCritical Quality Attributes (CQAs) including length, thickness, friability, weight variation, hardness test and disintegration time of Ciprofloxacin tablet to study whether the ciprofloxacin immediate release tablets of different pharmaceutical companies available in the Bangladeshi market to assess whether they are compliant to BP or USP guidelines in respect of physical parameters. We have also performed statistical analysis and found that that all the tablets from different brands are within the BP or USP requirements. So, from the study, we reached the conclusion that the critical quality attributes for ciprofloxacin immediate release tablets of different pharmaceutical companies in Bangladesh ensure the appropriateness of their strength, purity, release of the API from SDFs, and stability.

KEYWORDS: Ciprofloxacin; Critical Quality Attributes; Drug Release; Immediate Release; Stability; Strength

Download this article as:| Copy the following to cite this article: Arefin P, Ahmed R, Habib M. S, Bhattacharjee S. C, Chakraborty D, Das S, Karmakar D, Bhowmik D. Evaluation of Critical Quality Attributes of Immediate Release Ciprofloxacin Tablets of Different Pharmaceutical Companies in Bangladesh. Biosci Biotech Res Asia 2020;17(4). |

| Copy the following to cite this URL: Arefin P, Ahmed R, Habib M. S, Bhattacharjee S. C, Chakraborty D, Das S, Karmakar D, Bhowmik D. Evaluation of Critical Quality Attributes of Immediate Release Ciprofloxacin Tablets of Different Pharmaceutical Companies in Bangladesh. Biosci Biotech Res Asia 2020;17(4). Available from: https://bit.ly/2KtjKxp |

Introduction

Critical Quality Attributes (CQAs) refers to a physical, chemical, biological, or microbiological featureof a product that must be within an appropriate range, or limit, or distribution to confirm the expected quality.1,2 CQAs are generally related to the active pharmaceutical ingredients (API), excipients, intermediates (in-process materials), and drug product. For solid dosage forms (SDFs) like tablets or capsules that are taken orally, CQAs are generally the aspects that determine the strength, purity, release of the API from SDFs, and stability. For other types of dosage forms, CQAs include additional aspects specific to that dosage form, for instance, sterility for parenteral products,aerodynamic features for metered dose inhalers (MDIs), and adhesion for transdermal patches. CQAs is an important factor in Pharmaceutical development.3The recently developed approach of drug development, ‘Quality By Design’ (QBD) include design involving the parameter ranges for all CQAs to ensure the product complies the quality target product profile (QTPP). 2

Substandard and counterfeit drugs have been a major concern in recent days. There are a number of instances that account for substandard and fraudulent medications in the global market. Substandard pharmaceutical products do not follow the specifications and are ineffective and even hazardous to the patients4,5. A study in 2017 showed that globally, about 10% of the pharmaceutical dosage forms were claimed to be counterfeit products, but this number increased to 25% for developed countries, and surpassed 50% in some countries, as reported by World Health Organization (WHO). The FDA reports that up to 25% of medications in developing states are not standard or fraudulent.In 2016, the volume of global trade in fraudulent pharmaceutical products was up to USD 4.4 billion, as per the OECD/EUIPO (2019) report which constitutes 0.84% of the estimated pharmaceutical goods imported worldwide 6.

By contributing more than 90 percent of the available drugs on the market, local pharmaceutical manufacturers have recently emerged as a game-changer. Bangladesh Pharmaceutical Market Future Opportunity Outlook 2025, a recentreport published in 2020, has demonstrated that Bangladesh Pharmaceutical Market has marketing prospects ofmore than US$ 6 Billion by 2025 with an absolute growth of 114% from 2019 levels and exports opportunity of more than US$ 450 Million by 2025. For the achievement of this goal, Bangladesh, like other countries, has to maintain the quality of the drugs and dosage forms by maintaining the critical quality attributes suggested by FDA.7

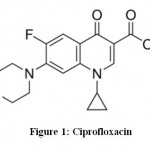

Ciprofloxacin tablets Ciprofloxacin is an antibiotic of fluoroquinolone group. It is used for the treatment of certain kinds of bacterial infections8. It exerts its effects by inhibiting DNA replication2. The enzyme inhibits the bacterial DNA gyrase (Topoisomerase II). This enzyme helps toinhibit relaxation of supercoiled DNA and consequently leads to breakage of dsDNA. 9–11

|

Figure 1: Ciprofloxacin |

The range of various brands of the same drug puts several prescribers in a challenging situation of choosing of an ‘ideal’ brand. In vitro research or drug quality control allows understanding in vivo dissolution pattern and bioavailability. Ciprofloxacin is quickly and well absorbed from the gastrointestinal tract when given orally in tablet form.8,10 The absolute bioavailability is about 70 percent with no significant loss by first-pass metabolism.The half-life is about 3.5-4.5 hours for Ciprofloxacin.In 1987, Ciprofloxacin was approved by the Food and Drug Administration (FDA) to be used in the United States as the first oral broad-spectrum antibiotic. It is amongst the most necessary medicines required for the basic health care system and is present in the World Health Organisation (WHO)Model list of essential medicines.12In our currentstudy, we have analyzed the critical quality attributes of ciprofloxacin tablets of different pharmaceutical industries of Bangladesh to study whether the companies provide the necessary quality attributes so that the drug can be dissolved properly in vivo and give required bioavailability.Six brands of immediate release Ciprofloxacin HCl 500 mg were randomly collected from Bangladeshi market and uniformity of weight, thickness, length, hardness, friability, and disintegration tests were carried out with the aim to assess their physical quality.13–16

Materials and Methods

Materials

Hydrochloric acid (HCl) was taken from Merck, Germany and Ciprofloxacin VETRANAL analytical standard (Sigma Aldrich) was used as standard.17,18Distilled water used throughout the work. Six different brands of Ciprofloxacin 500 mg tablets were purchased from the retail pharmacy and were called as Brand-A, Brand-B, Brand –C, Brand-D, Brand-E and Brand-F respectively. The labeled shelf life was three years from the date of manufacturing and the tablets were evaluated two years before the labeled expiry date.

Different Physical Test Methods

Thickness and Length

Table thickness and length wasmeasured by slide calipers. Tablet thickness and length should be in variation within ±5 % of standard value according to USP guidelines.13,21,16

Weight Variation Test

The aim of this test is to check the weight uniformity of manufactured batches, which essentially represents the uniformity of the presence of the active pharmaceutical ingredient. 20 tablets were arbitrarily taken and individually measured, and the mean was also evaluated. The difference between mean and individual tablet was calculated.13,16,22,23If not more than two tablets fall below the percentage range and if no tablet varies by more than 2 times the percentage limit, the tablet batch passes the USP ( United States Pharmacopeia) test.16-19The weight variation test was done for six different brands according to the Official USP guidelines.

Friability

Friability test was done using Roche friabilator. The friability test was done according to USP guidelines. 22,24–26The tablets are vulnerable to abrasion in the friability test. Thereby it is helpful to evaluate the strength of the tablet by this test.

Hardness

Tablet hardness of tablets of six brands was measured using Monsanto tablet hardness tester. Ten tablets were arbitrarily taken from each brand and then the pressure was given. The pressure point at which the tablet crushed was recorded. This is the hardness value for the specific tablet.16,23,27 The average hardness value was calculated and compared.

Disintegration

The disintegration test was performed using Disintegration apparatus (Copley). 0.1 N HCl at 37° C was used for disintegration test. The test was performed according to USP guidelines.10,19,28

Sample collection

Six different brands of Ciprofloxacin tablet available in Bangladesh were randomly selected. They were collected from retail pharmacies. For confidentiality purposes, they w ere designated as A,B, C, D, E and F.

Table 1: Brands of Ciprofloxacin

| Code | Dosage form | Tablet strength (mg) | Manufacturing date | Expiry date |

| A | Tablet | 500 | May, 2018 | Mar, 2021 |

| B | Tablet | 500 | Jan, 2018 | Jan, 2021 |

| C | Tablet | 500 | May, 2018 | May, 2021 |

| D | Tablet | 500 | May, 2018 | Apr, 2021 |

| E | Tablet | 500 | Mar, 2018 | Jul, 2021 |

| F | Tablet | 500 | Mar, 2018 | Mar, 2021 |

Result and Discussion

Thickness Test

Table shows that thickness of all brands of ciprofloxacin tablets is acceptable according to USP/BP specification.

Table no 2: Thickness studies for six brands

| Thickness (mm) | ||||||

| Sl no | Brand A | Brand B | Brand C | Brand D | Brand E | Brand F |

| 1 | 4.85 | 6.44 | 5.66 | 6.51 | 4.94 | 5.42 |

| 2 | 4.86 | 6.47 | 5.63 | 6.51 | 4.95 | 5.42 |

| 3 | 4.86 | 6.46 | 5.63 | 6.50 | 4.94 | 5.41 |

| 4 | 4.89 | 6.47 | 5.63 | 6.50 | 4.88 | 5.40 |

| 5 | 4.81 | 6.44 | 5.64 | 6.51 | 4.96 | 5.38 |

| 6 | 4.93 | 6.46 | 5.57 | 6.50 | 4.94 | 5.42 |

| 7 | 4.90 | 6.51 | 5.45 | 6.50 | 4.94 | 5.42 |

| 8 | 4.86 | 6.44 | 5.60 | 6.50 | 4.94 | 5.41 |

| 9 | 4.90 | 6.51 | 5.64 | 6.50 | 4.94 | 5.42 |

| 10 | 4.93 | 6.43 | 5.61 | 6.50 | 4.94 | 5.42 |

| Mean | 4.879 | 6.463 | 5.606 | 6.503 | 4.937 | 5.412 |

| Standard Deviation | 0.038 | 0.028 | 0.060 | 0.005 | 0.021 | 0.013 |

Length Test

Length of tablets can be dimensionally described and controlled. Tablet length should be within ±5 % of standard value according to USP/BP specification. Table 3 shows that, the length of brand-B shows less deviation compared to the brand-C, brand-A, brand-E, brand-D and brand-F. But all brands are acceptable according to USP/BP specification.

Table 3: Length studies for six brands

| Length (mm) | ||||||

| Sl no | Brand A | Brand B | Brand C | Brand D | Brand E | Brand F |

| 1 | 19.26 | 20.72 | 19.32 | 18.18 | 18.28 | 17.86 |

| 2 | 19.27 | 20.72 | 19.32 | 18.17 | 18.28 | 17.87 |

| 3 | 19.27 | 20.71 | 19.34 | 18.17 | 18.30 | 17.84 |

| 4 | 19.27 | 20.72 | 19.37 | 18.18 | 18.30 | 17.86 |

| 5 | 19.27 | 20.72 | 19.32 | 18.17 | 18.28 | 17.86 |

| 6 | 19.27 | 20.71 | 19.31 | 18.18 | 18.30 | 17.86 |

| 7 | 19.26 | 20.72 | 19.33 | 18.18 | 18.28 | 17.86 |

| 8 | 19.25 | 20.71 | 19.33 | 18.17 | 18.28 | 17.85 |

| 9 | 19.27 | 20.71 | 19.32 | 18.17 | 18.30 | 17.86 |

| 10 | 19.26 | 20.72 | 19.32 | 18.17 | 18.30 | 17.86 |

| Mean | 19.265 | 20.716 | 19.328 | 18.174 | 18.29 | 17.858 |

| Standard Deviation | 0.007 | 0.005 | 0.017 | 0.005 | 0.010 | 0.008 |

Weight Variation Test

All the brands conformed to the USP guidelines of weight variation test as Table 4 shows. Weight of two tablets should not differ from the average weight not more than 5%. Table 4 shows that the weight of brand-B and brand-C shows less deviation compared to the brand-A, brand-D, brand-E, brand-F. But all brands were found topass according to USP/BP specification.

Table 4: Weight variation studies for six brands

| Individual Weight Variations (gm) | ||||||

| Sl no | Brand A | Brand B | Brand C | Brand D | Brand E | Brand F |

| 1 | 0.71 | 0.85 | 0.83 | 0.79 | 0.73 | 0.70 |

| 2 | 0.71 | 0.87 | 0.83 | 0.79 | 0.73 | 0.71 |

| 3 | 0.71 | 0.88 | 0.83 | 0.78 | 0.74 | 0.71 |

| 4 | 0.70 | 0.86 | 0.85 | 0.79 | 0.74 | 0.68 |

| 5 | 0.72 | 0.85 | 0.81 | 0.79 | 0.71 | 0.69 |

| 6 | 0.72 | 0.85 | 0.82 | 0.78 | 0.71 | 0.68 |

| 7 | 0.73 | 0.85 | 0.83 | 0.79 | 0.73 | 0.71 |

| 8 | 0.71 | 0.85 | 0.83 | 0.78 | 0.73 | 0.69 |

| 9 | 0.73 | 0.86 | 0.81 | 0.79 | 0.73 | 0.70 |

| 10 | 0.70 | 0.87 | 0.81 | 0.79 | 0.72 | 0.69 |

| Mean | 0.714 | 0.859 | 0.825 | 0.787 | 0.727 | 0.696 |

| Standard Deviation | 0.011 | 0.011 | 0.013 | 0.005 | 0.010 | 0.012 |

Hardness Test

The capacity of tablets to survive handling without cracking or chipping is shown by the hardness. It may influence friability and disintegration as well. The harder thetablet, the more time it takes to disintegrate. Table 5 shows that brand A and B had less hardness while brands C, D, E, F could not break at 5 kg/cm². So, brand C, D, E, F is preferable according to USP/BP specification but brand A, B show less deviation.

Table 5: Hardness studies for six brands

| Hardness (kg/cm²) | ||||||

| Sl no | Brand A | Brand B | Brand C | Brand D | Brand E | Brand F |

| 1 | 3 | 3.5 | 6 | 4 | 6 | 6.5 |

| 2 | 3 | 3.5 | 5.5 | 4 | 6 | 6 |

| 3 | 3 | 3.5 | 6 | 4 | 5.5 | 6.5 |

| 4 | 3 | 3.5 | 6.5 | 3.5 | 6 | 6 |

| 5 | 3 | 3.5 | 4 | 4 | 6 | 5 |

| 6 | 3.5 | 3.5 | 6.5 | 4 | 6 | 5.5 |

| 7 | 3 | 4 | 6.5 | 4 | 6 | 6 |

| 8 | 3 | 4 | 4 | 4 | 6 | 6 |

| 9 | 3.5 | 4 | 6 | 4 | 6 | 5.5 |

| 10 | 3 | 4.5 | 6 | 3.5 | 6 | 5.5 |

| Mean | 3.10 | 3.75 | 5.7 | 3.9 | 5.95 | 5.85 |

| Standard Deviation | 0.211 | 0.354 | 0.949 | 0.211 | 0.158 | 0.474 |

Friability Test

The USP and BP specification for friability is not more than 1%. Friability for all the brands was below 1%. The value of friability that shown in table 6 of brand A is 0.140 % and brand C is 0.121% but it could be applicable because percent friability not more than 1% of USP/ BP specification is acceptable.

Table 6: Friability studies for six brands

| Sl no | Brands | Average

Weight of tablet before test (gm) |

Average

Weight of tablet after test (gm) |

Loss due to friability | Friability (%) | USP/BP

Specification |

Deviation from BP/USP |

| 1 | A | 8.24 | 8.23 | 0.01 | 0.140 |

Not more than 1% |

Pass the requirements according to USP/BP |

| 2 | B | 7.88 | 7.88 | 0 | 0 | ||

| 3 | C | 7.24 | 7.23 | 0.01 | 0.121 | ||

| 4 | D | 6.94 | 6.94 | 0 | 0 | ||

| 5 | E | 7.24 | 7.24 | 0 | 0 | ||

| 6 | F | 6.94 | 6.94 | 0 | 0 |

Disintegration Test

Disintegration could be directly related to dissolution and subsequent bioavailability of a drug. All the brands complied with compendia specifications for disintegration. The BP specification is that uncoated tablets and film coated tablet should disintegrate within 15 min and coated tablets should disintegrate within 30 min while USP/BP specifies that un coated and film coated tablets should disintegrate within 15 min. Table 7 shows that brand A, brand B, brand C, brand D, brand E, brand F disintegrate within 15 min that fulfills the requirement of USP specification.

Table 7: Disintegration test results

| Sl. No. | Individual tablet DT

(Min:Sec) |

|||||

| A | B | C | D | E | F | |

| 1 | 2:40 | 2:24 | 10:38 | 1:53 | 5:00 | 2:25 |

| 2 | 2:46 | 2:31 | 12:00 | 1:54 | 6:12 | 2:30 |

| 3 | 2:56 | 2:50 | 11:00 | 1:50 | 6:34 | 2:06 |

| 4 | 2:27 | 2:57 | 12:24 | 1:57 | 4:17 | 2:13 |

| 5

|

2:35 | 2:44 | 11:55 | 1:44 | 6:46 | 2:19 |

| 6 | 3:04 | 2:39 | 10:45 | 1:53 | 5:56 | 2:36 |

| Average Dissolution Time (Min:sec) | 2:44 | 2:46 | 11:27 | 1:51 | 5:47 | 2:35 |

| BP/USP specification | For uncoated or Film coated tablet Within 15 min | |||||

| Comments | Pass the requirements according to USP/BP | |||||

We have found that the length, thickness, friability, weight variation, hardness test and disintegration time of Ciprofloxacin tablet were compliant to BP or USP guidelines. Tablet formulations should have adequate hardness and minimum friability to uphold its mechanical strength and stability which are important resulting factors of critical quality attributes (CQAs). Again, hardness of a tablet can affect the disintegration and dissolution, overall the release of the active pharmaceutical ingredient from the dosage form which is another resulting factor of critical quality attribute. All parameters assay result show that all brands are within the pharmacopoeial requirements. Ciprofloxacin tablets from different pharmaceutical companies showed significant differences in weight variation, hardness, and disintegration probably because of the process factor and variation in formulation parameters from manufacturer to manufacturer. But it shows less deviation in length, thickness and friability. The critical quality attributes indicate that these tablets would have desired dissolution pattern in the body after administration.

Conclusion

Ciprofloxacin is a second-generation fluoroquinolone derivative that exerts its effects by inhibiting bacterial DNA gyrase (TopoisomeraseII). It is used for the treatment of bacterial gastroenteritis, respiratory tract infections, controlling bronchitis and pneumonia caused by Gram negative bacteria. We have studied the Critical Quality Attributes including length, thickness, friability, weight variation, hardness test and disintegration time of Ciprofloxacin tablet to study whether the ciprofloxacin immediate release tablets of different pharmaceutical companies available in the Bangladeshi market to assess whether they are compliant to BP or USP guidelines in respect of physical parameters. The statistical analysis of the results shows that all the tablets from different brands are within the BP or USP requirements.The tablets are expected to show desired dissolution pattern in the body. So, from the study, we reached the conclusion that the critical quality attributes for ciprofloxacin immediate release tablets of different pharmaceutical companies in Bangladesh ensure the appropriateness of their strength, purity, release of the API from SDFs, and stability.

Acknowledgement

We are grateful to Department of Pharmacy,ASA University Bangladesh for the research facilities provided.

Conflict of interest

The research has no conflict of interest.

References

- Zhang, L.; Mao, S. Application of Quality by Design in the Current Drug Development. Asian Journal of Pharmaceutical Sciences2017, 12 (1), 1–8. https://doi.org/10.1016/j.ajps.2016.07.006.

CrossRef - Claycamp, H. G.; Kona, R.; Fahmy, R.; Hoag, S. W. Quality-by-Design II: Application of Quantitative Risk Analysis to the Formulation of Ciprofloxacin Tablets. AAPS PharmSciTech2016, 17 (2), 233–244. https://doi.org/10.1208/s12249-015-0349-2.

CrossRef - Adminstration, U. S. F. and D. Guidance for Industry – Q8(R2) Pharmaceutical Development; U.S. Food and Drug Administration, 2016.

CrossRef - Arefin, P. A Review on the Ayurvedic Management of Causes and Symptoms of Bronchial Asthma; Vol. 9.

CrossRef - Arefin, A.; Arefin, P.; Arefin, S. Study on Awareness about Food Adulteration and Consumer Rights among Consumers in Dhaka, Bangladesh. Journal of Health Science Research2020, 0 (0), 23–31. https://doi.org/10.18311/jhsr/0/25038.

CrossRef - Trade in Counterfeit Goods and Free Trade Zones; Illicit Trade; OECD, 2018. https://doi.org/10.1787/9789264289550-en.

CrossRef - Bangladesh Pharmaceutical Market Future Opportunity Outlook 2025; 2020.

- Joda, A. E.; Tayo, F.; Aina, B. A. Quality Assessment of Ciprofloxacin Tablets Obtained from Community Pharmacies in Lagos, Nigeria. Ife Journal of Science2018, 20 (1), 155. https://doi.org/10.4314/ijs.v20i1.16.

CrossRef - Sharma, P. C.; Jain, A.; Jain, S.; Pahwa, R.; Yar, M. S. Ciprofloxacin: Review on Developments in Synthetic, Analytical, and Medicinal Aspects. Journal of Enzyme Inhibition and Medicinal Chemistry2010, 25 (4), 577–589. https://doi.org/10.3109/14756360903373350.

CrossRef - Fourcroy, J. L.; Berner, B.; Chiang, Y.-K.; Cramer, M.; Rowe, L.; Shore, N. Efficacy and Safety of a Novel Once-Daily Extended-Release Ciprofloxacin Tablet Formulation for Treatment of Uncomplicated Urinary Tract Infection in Women. Antimicrobial Agents and Chemotherapy2005, 49 (10), 4137–4143. https://doi.org/10.1128/AAC.49.10.4137-4143.2005.

CrossRef - Fahmy, S.; Abu-Gharbieh, E. In Vitro Dissolution and In Vivo Bioavailability of Six Brands of Ciprofloxacin Tablets Administered in Rabbits and Their Pharmacokinetic Modeling. BioMed Research International2014, 2014, 1–8. https://doi.org/10.1155/2014/590848.

CrossRef - Uddin, M. S.; Mamun, A. Al; Hossain, M. S.; Asaduzzaman, M.; Sarwar, M. S.; Rashid, M.; Herrera-Calderon, O. In Vitro Quality Evaluation of Leading Brands of Ciprofloxacin Tablets Available in Bangladesh. BMC Research Notes2017, 10 (1), 185. https://doi.org/10.1186/s13104-017-2507-y.

CrossRef - Evagelin, M. P.; Elisha, Y.; Kumar, P. P.; Lakshmi, G. S.; Arathi, K. Design and Evaluation of Amlodipine and Losartan Potassium Immediate Release Tablets by Direct Compression Method. The Journal of Medical Research2020, 6 (3), 103–105. https://doi.org/10.31254/jmr.2020.6310.

CrossRef - Panda, N.; Reddy, A. V.; Subba Reddy, G. V.; Panda, K. C. Formulation Design and in Vitro Evaluation of Zolmitriptan Immediate Release Tablets Using Primojel and AC-Di-Sol. Journal of Pharmaceutical Sciences and Research2015, 7 (8), 545–553.

- World Health Organization. Revision of Monograph on Tablets. International Pharmacopeia REVISION OF MONOGRAPH ON TABLETS Final text for addition to The International Pharmacopoeia2011, No. March, 1–6.

- Nyol, S.; Gupta, M. M. Immediate Drug Release Dosage Form: A Review. Journal of Drug Delivery and Therapeutics2013, 3 (2), 155–161. https://doi.org/10.22270/jddt.v3i2.457.

CrossRef - Arefin, P.; Hasan, I.; Reza, M. S. Design, Characterization and in Vitro Evaluation of HPMC K100 M CR Loaded Fexofenadine HCl Microspheres. SpringerPlus2016, 5 (1). https://doi.org/10.1186/s40064-016-2322-2.

CrossRef - Arefin, P.; Hasan, I.; Islam, M. S.; Reza, M. S. Formulation and In Vitro Evaluation of Eudragit RL 100 Loaded Fexofenadine HCl Microspheres. Bangladesh Pharmaceutical Journal2016, 19 (1), 58–67. https://doi.org/10.3329/bpj.v19i1.29240.

CrossRef - Kassahun, H.; Asres, K.; Ashenef, A. In Vitro and In Vivo Quality Evaluation of Glibenclamide Tablets Marketed in Addis Ababa, Ethiopia. Journal of Pharmaceutics2018, 2018, 1–7. https://doi.org/10.1155/2018/7916368.

CrossRef - Matji, A.; Donato, N.; Gagol, A.; Morales, E.; Carvajal, L.; Serrano, D. R.; Worku, Z. A.; Healy, A. M.; Torrado, J. J. Predicting the Critical Quality Attributes of Ibuprofen Tablets via Modelling of Process Parameters for Roller Compaction and Tabletting. International Journal of Pharmaceutics2019, 565, 209–218. https://doi.org/10.1016/j.ijpharm.2019.05.011.

CrossRef - Kar, A.; Amin, M. N.; Hossain, M. S.; Mukul, M. E. H.; Rashed, M. S. U.; Ibrahim, M. Quality Analysis of Different Marketed Brands of Paracetamol Available in Bangladesh. International Current Pharmaceutical Journal2015, 4 (9), 432–435. https://doi.org/10.3329/icpj.v4i9.24473.

CrossRef - Rahman, M. Z.; Ahamed, S. K.; Banik, S.; Hossain, M. S. Release Profile of Losartan Potassium from Formulated Sustained Release Matrix Tablet. Bangladesh Pharmaceutical Journal2015, 16 (2), 177–183. https://doi.org/10.3329/bpj.v16i2.22301.

CrossRef - Karim, S.; Bhuiyan, M. A.; Rana, M. S. Formulation and in Vitro Evaluation of Glimepiride Sustained Release Tablets: Comparison with Immediate Release Tablets. Bangladesh Pharmaceutical Journal2015, 18 (2), 157–162. https://doi.org/10.3329/ bpj.v18i2.24315.

CrossRef - Gaikwad, S. S.; Chafle, S. A.; Morris, P. S.; Avari, J. G. Development and Evaluation of Bilayer Tablets of Combination of Antibiotics for the Treatment of Sexually Transmitted Disease. Brazilian Journal of Pharmaceutical Sciences2016, 52 (3), 555–566. https://doi.org/10.1590/s1984-82502016000300020.

CrossRef - Rayakwar, N.; Singh Dangi, Y.; Professor, A. Development and Characterization of Controlled Release Bilayered Tablets of Citicoline Sodium. Journal of Drug Delivery and Therapeutics2019, 9 (2-s), 125–131.

- Nasrin, N.; Asaduzzaman, M.; Mowla, R.; Rizwan, F.; Alam, A. A Comparative Study of Physical Parameters of Selected Ketorolac Tromethamine Tablets Available in the Pharma Market of Bangladesh. Journal of Applied Pharmaceutical Science2011, 1 (8), 101–103.

- Khreit, O. I.; Alkailani, H. A.; Alqathafi, W. S. A Comparative Study of Physical and Chemical Parameters of Selected Paracetamol Tablets Available in the Pharma Market of Libya. Der Pharma Chemica2017, 9 (2), 1–6.

- United States Pharmacopoeia. Disintegration Test for Tablets and Capsules. The International Pharmacopoeia2016, No. 6, 1–4.

(Visited 486 times, 1 visits today)

This work is licensed under a Creative Commons Attribution 4.0 International License.