Manuscript accepted on : May 25, 2011

Published online on: 28-06-2011

Performance Study of Preheated Degummed Jatropha oil on Agricultural Diesel Engine

Anil Kumar Dubey1, R. M Sarviya2 and A. Rehman2

1Division of Agricultural Energy and Power, Central Institute of Agricultural Engineering, Bhopal - 462 038 India.

2Department of Mechanical Engineering, Maulana Azad National Institute of Technology, Bhopal - 462 051 India.

ABSTRACT: A study was conducted on the use of degummed jatropha oil (DGJO) as an alternate fuel for medium speed CI engines used in agricultural sector. The viscosity of jatropha oil was reduced to certain extent by degumming process as well as by pre heating the test fuel. The fuel prepared by blending DGJO in fossil diesel was preheated just before the injector using engine exhaust gas waste heat up to 70 °C. The pre heating of fuel inlet has shown improvement in engine performance. The brake specific fuel consumption and brake thermal efficiency were improved by 13.3% and 10.6% respectively when compared with the performance observed with unheated DGJO based test fuel. The engine was successfully operated with pre heated (70 °C) DGJO100 at 20.9% of maximum brake thermal efficiency. The maximum brake thermal efficiency with fossil diesel was observed to be 24.4%.

KEYWORDS: Pre heated degummed jatropha oil; diesel fuel; CI engine; fuel inlet temperature; fuel property

Download this article as:| Copy the following to cite this article: Dubey A. K, Sarviya R. M, Rehman A. Performance Study of Preheated Degummed Jatropha oil on Agricultural Diesel Engine. Biosci Biotech Res Asia 2011;8(1) |

| Copy the following to cite this URL: Dubey A. K, Sarviya R. M, Rehman A. Performance Study of Preheated Degummed Jatropha oil on Agricultural Diesel Engine. Biosci Biotech Res Asia 2011;8(1). Available from: https://www.biotech-asia.org/?p=9291 |

Introduction

India has an agriculture based economy and agriculture is an energy transformation process as energy is produced and consumed in it. Because of mechanized farming, the amount of energy consumption has increased multi fold in terms of oil and electricity. Rapidly increasing prices and uncertainties on availability of petroleum fuel requires effort to reduce dependence on petroleum fuels for better economy and environment. Liquid bio fuels are renewable fuels and have been proved to be good substitutes for petroleum oil in transportation and agriculture sector. These fuels are gaining importance as a solution for environmental degradation, energy security, restricting import, rural employment and agricultural economy. The use of vegetable oil is an attractive alternate of diesel fuel in rural areas to run tractors, pumps and small engines for use in irrigation, electricity generation purposes and domestic production of fuels in the emergency periods (Agrwal D, 2007).

There are a number of plants, which produce non edible oils could be used in IC engines. Non-edible vegetable oils will be economical and can be grown easily in waste land with less maintenance. The Jatropha curcas is a draught resistance plant and requires little irrigation and grows in all types of soil ( Banapurmath,2008). The oil content in Jatropha seed is 34.4%. The energy content of oil is 39.6MJ/kg (Acthen,2008).The jatropha oil has great potential as alternate fuel for IC Engines hence selected for study. The problems associated with the use of vegetable oil are their high viscosity, high molecular weight and high density. The following four techniques could be used to reduce the viscosity of vegetable oils are i) Heating, ii) Dilution/blending, iii) Micro-emulsion and iv) Transesterification. Nwafor et al. (2003) experimented with preheated (at 70 °C) straight vegetable oil in an indirect injected single-cylinder diesel engine and concluded that fuel heating was beneficial at low-speed operation and under part-load test conditions. At present, researchers and industries are trying to develop engine and the processing of the vegetable oils so that it could be used 100% in engine without any difficulty.

The aim of the study is to assess the performance of medium speed engines used in agricultural sector with degummed jatropha oil and their blends in fossil diesels. The viscosity of jatropha oil was reduced to certain extent by degumming process and further reduced by pre heating of DGJO and their blends using engine exhaust gas waste heat. The performance parameters investigated with preheated DGJO and their blends in fossil diesel are brake specific fuel consumption (BSFC), brake specific energy consumption (BSEC), brake thermal efficiency (BTHE) and exhaust gas temperature (EGT).

Experimental setup and experiments

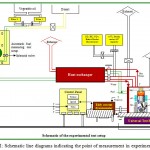

A single cylinder 4-Stroke water-cooled diesel engine developing 3.7 kW at 1500 rpm was used for the present study. The schematic diagram of the experimental setup is shown in Fig. 1. An eddy current dynamometer coupled with engine on universal test bed was used. The test rig has the provision to measure the engine speed, torque, time for 75 ml fuel consumption and operating temperatures of engine. The heat exchanger was fitted to heat the high pressure fuel pipe line connecting fuel pump and injector. The waste heat of exhaust gases were used to raise the temperature going to injector by 70 °C. The provision was made to control the flow of exhaust gas temperature to maintain the desired fuel temperature of 50°C and 70 °C. Experiments were initially carried out on the engine-using diesel as the fuel to provide base line data. The cooling water temperature at the outlet was maintained at 65 °C. The engine speed was kept constant 1500 rpm at all the test loads and the power output was varied. Fig 1 Experimental Setup equipped with various equipment for testing the engine.

|

Figure 1: Schematic line diagrams indicating the point of measurement in experimental setup. |

Test fuel

Production of degummed jatropha oil (DGJO)

The hot water degumming process was used to remove the gums present in the Jatropha oil to improve the viscosity up to certain limit so that the blends of DGJO with diesel can be used in diesel engine satisfactorily. The raw oil was heated up to 70 °C in water bath. The hot water (3% of oil) was added in hot oil and stirred to get reacted with phosphetides for 40 minutes duration. The reacted oil was cooled to ambient temperature and centrifuged at 3000 rpm for 30 minute duration to separate the gums and phosphetides from oil. The oil was further dried in oven to remove the traces of water at low temperature (80 °C). The dried degummed oil is used to prepare test fuel for used as engine fuel during performance test.

Preparation of Test Fuel

The test fuels of degummed jatropha oil were prepared with diesel on volume basis. The degummed Jatropha oil in 20, 40, 60, 80 and 100 percent on volume basis was blended with HSD. The blends were prepared by proper mixing both the fuels and no phase separation was notice with HSD. The prepared 20 percent DGJO was blended with 80 percent fossil diesel (HSD) on volume basis for use as engine fuel is identified as DGJO20. Similarly other test fuels prepared with 40, 60, 80 and 100 percent DGJO are identified as DGJO40, DGJO60, DGJO80 and DGJO100.

Results and discussion

Characterization of test fuels

The degummed jatropha oil and fossil diesel were characterized for fuel properties and presented in table 1

Table 1: Fuel Properties of Diesel, JO and DGJO

| Properties | Diesel | JO | DGJO |

| Density at 20 ºC g/cc | 0.852 | 0.926 | 0.909 |

| Specific Gravity at 20 ºC | 0.854 | 0.928 | 0.91 |

| Viscosity at 20 cst | 3.91 | 47.3 | 39.6 |

| Calorific value , kj/kg | 44215 | 38989 | 39358 |

| Flash point, ºC | 76 | 228 | 216 |

| Cloud point, ºC | -6 | 6 | 4 |

| Pour point , ºC | -13 | 1 | -2 |

| Acid value mg/NaOH/g | 0.26 | 2.16 | 1.82 |

| Carbon residue ,% | 0.275 | 0.875 | 0.53 |

| Ash content , % | 0.005 | 0.134 | 0.1 |

Performance Testing of Engine

The performance characteristic of engine was evaluated by using different blends of degummed Jatropha oil with fossil diesel (HSD). The data were analyzed to compare the effects of degummed Jatropha oil on engine performance i.e. brake specific fuel consumption(BSFC), brake specific energy consumption (BSEC), brake thermal efficiency(BTE) and exhaust gas temperature( EGT) are discussed below.

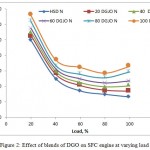

Brake specific fuel consumption

The variation of brake specific fuel consumption with load for different blends of degummed Jatropha oil is shown in fig 2. The BSFC showed decreasing trend with the increase in rated power and it increased with increase in concentration of degummed jatropha oil in test fuel. Thus the BSFC was minimum for diesel fuel at full load and maximum with 100 percent degummed jatropha oil. The analysis of data shows that engine load had significant effect on BSFC. The results are in line with the trend observed by Rama Das (2004) and Chauhan (2010) . The difference in specific gravity and calorific value between DGJO and HSD fuel might have contributed for significant increase in BSFC of engine fuel with DGJO + HSD fuel blends.

|

Figure 2: Effect of blends of DGO on SFC engine at varying load.

|

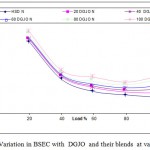

Brake specific energy consumption

The variation of BSEC with the increase in power output and with the increase in concentration of DGJO in diesel fuel is presented in figure3. The result indicated the BSEC decrease with the increase in output up to 80% of load and after that BSEC again increases. The BSEC also increased with increase in concentration of DGJO with each blend of vegetable oil in diesel at all the stages. The minimum Brake specific energy consumption was observed at maximum power output with diesel fuel (14.6 MJ/kWh) followed by DGJO20 (15.9 MJ/kWh). The minimum BSEC at DGJO40, DGJO60, DGJO80 and DGJO100 was observed 16.8 MJ/kWh, 17.4 MJ/kWh, 18.4 MJ/kWh and 19.1 MJ/kWh respectively. The percent increases in BSEC for DGJO100 as compare to diesel fuel was 30.4%. Similar trend was observed by Chauhan (2010).

|

Figure 3: Variation in BSEC with DGJO and their blends at varying load. |

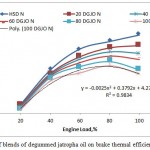

Brake thermal efficiency

The variation of brake thermal efficiency (BTHE) with increase in power output and DGJO concentration is presented in Figure 4. The result shows that the BTHE increased up to 80% of power output but after that decreases. The BTHE also decreased with the increase in concentration of DGJO in test fuel at all levels of power output in comparison with fossil diesel. The brake thermal efficiency was found increasing up to 80% of rated power beyond that the thermal efficiency was found decreasing. A similar trend of results of brake thermal efficiency was also reported by many researchers including Chauhan(2010), Mazed(1985), Mathur(1985) and shyam(1984).

|

Figure 4: Effect of blends of degummed jatropha oil on brake thermal efficiency at varying load. |

Exhaust gas temperature

The variation of exhaust gas temperature with the different power output for fossil diesel and blends of DGJO are presented in figur5. The result shows that with the increase in power output the exhaust gas temperature also increased with all the cases. The exhaust gas temperature also increases with the increase in DGJO concentration in test fuel. The increase in temperature may be due to the delayed combustion because of slower combustion characteristics of vegetable oils. The maximum exhaust gas temperature was achieved 531°C which was 20.4% higher than the diesel fuel. Similar trend of results was also observed by Pramanik(2003) and Pugzhvadivn(2005) who worked with the other vegetable oil. The increase in exhaust gas temperature with the increase in preparation of vegetable oil

|

Figure 5: Effect of blends of DGO on Exhaust Gas Temperature at varying load.

|

Effect of preheating of test fuels on engine performance

Effect of preheating of fuel on BSFC

Effect of preheating of blends of degummed Jatropha oil on brake specific fuel consumption is given in figure 6. The result shows that preheat of DGJO have reduced the BSFC at all the loads for all the blends of DGJO in diesel. The BSFC for DGJO100 at maximum power ratings for different fuel inlet temperature i.e. no heating, 50˚C and 70˚C temperature were 528 g/kWh, 511 g/kWh and 458 g/kWh respectively. The preheating of test fuel have improved the atomization and there by improvement in combustion which has resulted in reduction of BSFC. The BSFC was decreased by 3.2% and 13.3%when DGJO100 test fuel was used at 50°C and 70 °C respectively as compared to unheated fuel. The BSFC with preheat of DGJO based test fuel at 70˚C was higher than the fossil diesel. The BSFC at maximum power with DGJO20 and DGJO100 were 4.5% and 38.4 % higher than the diesel fuel respectively.

|

Figure 6: Effect of preheating of test fuel on DGJO and its blends.

|

Effect of preheat of DGJO on brake thermal efficiency

The effect of preheat of DGJO based test fuel on brake thermal efficiency at engine power ratings of 60, 80 and 100% of rated power are presented in figure 7. The result shows that increase in brake thermal efficiency was observed with pre heating of DGJO based test fuels. The percentage change in brake thermal efficiency for DGJO as compared to fossil diesel is shown in figure 8. The maximum brake thermal efficiency with different fuel inlet temperature of DGJO100 i.e. unheated and pre heated at 50˚C and 70˚C conditions were 18.9%, 19.5% and 20.9% respectively. BTHE at maximum power ratings at 70˚C fuel inlet temperature for DGJO20, DGJO40, DGJO60, DGJO80 and DGJO100 were 24.1%, 23.5%, 22.3%, 20.6% and 19.9% respectively. The findings are in line with Chauhan 2010.

|

Figure 7: Variation of efficiency with different blends of DGJO. |

|

Figure 8: Percent variation of brake thermal efficiency with different blends of DGJO. |

Effect of preheat on exhaust gas temperature

The effect of preheat of DGJO and their blends on exhaust gas temperature shows that preheating of blends has shown increase in exhaust gas temperature. The exhaust gas temperature at maximum power ratings with blends DGJO20, DGJO40, DGJO60, DGJO80 and DGJO100 at 70˚C preheated test fuel were 508˚C, 527˚C, 538˚C, 549˚C and 561˚C respectively. These temperatures were 6.7%, 5.2%, 4.1%, 3.4% and 7.5% higher as compared to exhaust gas temperature observed with unheated test fuel. The exhaust gas temperature for unheated and heated DGJO100 test fuel at 50 ˚C and 70˚C were observed to be 522˚C, 548˚C and 561˚C respectively. These exhaust gas temperature with pre heated test fuel at 50˚C and 70˚C were 5.0% and 7.5% higher than the unheated test fuel.

Conclusion

The performance of engine with increase in concentration of DGJO in test fuel showed increase in BSFC and decrease in brake thermal efficiency. The preheating of DGJO based test fuel at 70 ˚C has shown significant improvement in engine performance as compared to unheated test fuel. The BSFC and BTHE with DGJO100 at 70 ˚C fuel inlet temperature were improved by 13.3% and 10.6% respectively. Increase in exhaust gas temperature was found with increase in fuel inlet temperature. The pre heated DGJO could be used as an alternate fuel with 20.9 % maximum brake thermal efficiency without any operational problem.

References

- Achten WMJ, Verchot L, Franken YJ, Mathijs E, singh VP,Aerts R and Muys B; 2008; Jatropha biodiesel production and use; Biomass and Bio Energy,32;1063-1084.

- Agrwal D, Agrwal AK,2007; Performance and emission characteristics of jatropha oil in a direct ignition compression ignition engine; applied Thermal engineering;27;2514-2523

- Banapurmath NR,Tewari PG and Hoshmath RS 2008; Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters; Renwable Energy,33,1982-1988.

- ChauhanBP, Kumar Naveen, Jun YD and Lee KB, 2010; Performance and emission study of preheated jatropha oil on medium capacity diesel engine; Energy, 35; 2484-2492.

- Mazed, M.A. , Summers, J.D. and Datchelder, D.G. 1985 . Engine endurance with peanut, soyabean and cotton seed oil fuels. Transaction of Am. Soc. Agric. Engrs.,28(5):1371-74

- Mathur, H.B. and Das , L.M. 1985 .Utilization of non edible wild oils as diesel engine fuels. Proceedings of bio energy society, Second convention and symposium 85, Oct.13-14, Hyderabad, India: 198-202.

- Nwafor O.M.I. 2003, The effect of elevated fuel inlet temperature on performance of diesel engine running on neat vegetable oil at constant speed conditions. Renewable Energy; 28: 171-181.

- Pramanik, K., 2003, Properties and use of jatropha curcas oil and diesel fuel blends in compression ignition engine, Renewable Energy (28), 239- 248

- Pugazhvadivu M. and Jeyachandran K.;2005, Investigations on the performance and exhaust emissions of a diesel engine using preheated waste frying oil as fuel; Renewable Energy, 30, 2189–2202

- Ramadhas, A S; Jayaraj, S and Muraleedharan, C. 2004, Use of vegetable oils as IC Engine fuels-A review; Renewable energy; 29: 727-742

- Shyam, M., Verma, S. R. and Pathak, B. S. 1984, Performance of 5 hp diesel engine with various blends of plant oils and diesel / Kerosene oils. J. Agril. Engg., 21(3) : 1-13.

This work is licensed under a Creative Commons Attribution 4.0 International License.