Manuscript accepted on : 08 July 2016

Published online on: --

Plagiarism Check: Yes

Fiza Nazir, H. R. Naik and Syed Zameer Hussain

Division of Post Harvest Technology, Sher-e-Kashmir University of Agricultural Sciences and Technology Kashmir Shalimar, Srinagar, J and K, India-190025.

Corresponding Author E-mail: mirfizanazir@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/2316

ABSTRACT: Taking broken rice flour as the base ingredient, apricot powder was used in this study for development of breakfast snacks using twin screw extruder. Response surface methodology using a central composite rotatable design was used to evaluate the effects of independent variables, namely composition (0-40% apricot), barrel temperature (110–190 oC), screw speed (150–550 rpm) and moisture content (12.5-22.5%) on product colour parameters (L*, a*, b*, chroma, hue angle and ∆E). Multiple regression equations were obtained to describe the effects of each variable on product responses (L*, a*, b*, chroma, hue angle and ∆E). The product responses were most affected by changes in composition, barrel temperature and to a lesser extent by screw speed and moisture content. Increase in temperature and apricot addition decreased luminosity; while increasing redness and yellowness of the extrudates compared to the control (0% apricot).

KEYWORDS: Color; apricot powder; rice broken; breakfast snacks; response surface methodology

Download this article as:| Copy the following to cite this article: Nazir F, Naik H. R, Hussain S. Z. Effect of Extrusion Conditions and Apricot Powder Incorporation on Colour Parameters of Rice Based Breakfast Snacks. Biotech Res Asia 2016;13(3). |

| Copy the following to cite this URL: Nazir F, Naik H. R, Hussain S. Z. Effect of Extrusion Conditions and Apricot Powder Incorporation on Colour Parameters of Rice Based Breakfast Snacks. Biotech Res Asia 2016;13(3). Available from: https://www.biotech-asia.org/?p=16034 |

Introduction

Extrusion being a combination of unit operations provides flexibility in terms of temperature control, mechanical shearing and product forms, which is best suited for ready-to-eat snack food manufacture [1]. Extrusion cooking can change the functionality of food ingredients in addition to usual benefits of heat processing [2]. Raw material undergoes a number of chemical and structural transformations such as gelatinisation of starch, protein denaturation, amylase and lipid complex formation and degradation reaction of vitamins and pigments [3]. Extruded snacks mostly are low in vitamins and minerals since they are made primarily from starch rich raw material (cereals/grains) owing to their good expansion. Consumers have become more health conscious during recent decades. There is an increasing consumer demand for value added food products, especially fruit, vegetables and other functional foods [4]. Enrichment of extruded snacks with nutritionally valuable ingredients is increasingly practised by many studies, wherein the addition of protein and fibre rich ingredients like legumes or whey protein is leading, and the addition of fruits and vegetables is studied to a lesser extent [5]. Colour of a food product plays a vital role in its consumer acceptance. Natural colours are assuming wider prominence with increasing public concern over safety aspect of synthetic colourants. In apricot the chief carotenoid derivative is β-carotene. The fruit has distinctively delicious taste, appealing smell, and varying colours from yellow to orange. In the presence of β-carotene, it is possible to observe yellow to orange colour in food. The use of natural colours prior to extrusion would not only add to visual appeal and acceptability, but could also form a suitable matrix for delivery of functional ingredients to consumers.

Response surface methodology (RSM) is an effective optimization tool wherein many factors and their interactions affecting the response can be identified with fewer experimental trials. RSM has been widely used in various fields of food processing including extrusion [6-7], food product development, media composition in biotechnology, bioprocessing such as enzymatic hydrolysis and fermentation. In this study apricot powder was blended with rice flour at different levels to obtain ready to eat extruded breakfast snack and the effect of extrusion variables and apricot powder addition on the colour coordinates of rice based extrudates was reported.

Materials and Methods

Materials

The paddy was procured from local market and shelled using Satake rice mill to obtain brown rice, which in turn was passed through rice polisher. The small rice brokens were ground in a lab mill model 3303 (Perten, Sweden) to a fineness that passes through 200µm sieve. Dried apricot was obtained from local market and ground into powder.

Preparation of sample

Blends were prepared from rice flour and apricot powder in definite ratios for carrying out 30 runs in the extruder. Moisture content of rice flour and blends was determined by oven drying method [8] and adjusted for different blend according to the experimental runs.

Extrusion processing

The extrusion was performed using a co-rotating intermeshing twin screw extruder model BC 21 (Clextral, Firminy, France). The barrel consisted of four zones heated electrically. The temperature distribution inside barrel varied from low at the zone next to the feeding to high at zone next to die. Temperature of the 1st, 2nd, and 3rd was maintained at 20, 30 and 40℃, respectively, throughout the study; while the temperature in last zone (compression and die section) was varied. The extruder was equipped with torque indicator which showed percent of torque in proportion the current drawn by drive motor. The raw material was fed into the extruder with a single-screw volumetric feeder. The extruder was thoroughly calibrated with respect to combinations of feed rate and screw speed to be used. The feed rate was varied for optimum functioning of extruder barrel corresponding to screw speed. Water pump injected water directly into extruder barrel to achieve desired moisture content of feed material. A cutter with four bladed knives and a die (6mm) made of stainless steel were used for shaping the extrudates.

Colour measurement

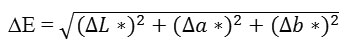

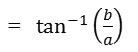

The colour of extrudates was measured using Hunter Lab Colourimeter, in terms of Hunter L* value (lightness, ranging 0–100 indicating black to white), a* value (+a* value indicates redness and−a* value indicates greenness) and b* value (+b* value indicates yellowness and −b*value indicates blueness). Total colour change (∆E), Chroma (CR), Hue angle (HA) were calculated from L*, a*and b* value according to below equations.

Chroma

![]()

Hue angle

Where ∆L = L*Sample – LControl, ∆a = a*Sample – a*Control, ∆b = b*Sample – b*Control

Extruded broken rice snack was used as control.

Experimental design and statistical analysis

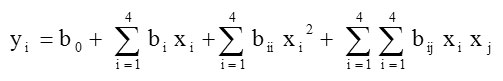

The experimental design was based on a central composite design for four independent variables and five levels. The independent variables considered in this study were barrel temperature (110°C to 190 °C), screw speed (150 rpm to 550 rpm), moisture content (12.5% to 22.5%) and apricot level (0 to 40%). Dependent variables were Hunter colour parameters (L*, a*, b*), chroma, Hue angle and ∆E. Response surface methodology was applied for investigating the effect of extrusion variables on product colour parameters. Responses obtained as a result of the proposed experimental design were subjected to regression analysis in order to assess the effects of composition (Rice: Apricot), moisture content, screw speed and barrel temperature on product characteristics. Second order polynomial regression models were established for the dependent variables to fit experimental data for each response using statistical software Design-Expert 8 (Stat-Ease Inc, Minneapolis, MN, USA).

where xi (i = 1, 2, 3, 4) are independent variables (Composition, Moisture, screw speed and barrel temperature respectively) and b0, bi, bii and bij are coefficient for intercept, linear, quadratic and interactive effects respectively. Data was analyzed by multiple regression analysis and statistical significance of the terms shall be examined by analysis of variance (ANOVA) for each response.

Results and Discussion

Effect of extrusion conditions on Colour parameters

According to the regression results, apricot powder level had a dominant effect on color parameters L*, a*, b*, chroma, hue angle and total color change of extrudates. The regression analysis for the determination of the desired constants yielded a regression coefficient (R2) of 0.9961, 0.9931, 0.9842, 0.9806, 0.9897, 0.9963 for color parameters L*, a*, b*, chroma, hue angle and ∆E, respectively. The parameter L* was negatively correlated with a* and b* values. On the other hand, a* and b* values were positively correlated with each other. Hunter colour parameters, chroma, hue angle and total colour change (∆) of extrudates under different extrusion conditions are shown in Table 1.

Table 1: Effect of extrusion on colour parameters

| Run | Extruder conditions | Colour parameters | ||||||||

| Composition (R:A) (%) | Moisture

(%) |

Screw speed (rpm) | Temperature (ºC) | L* | a* | b* | chroma | Hue angle | ∆E | |

| 1. | 90:10 | 15 | 250 | 130 | 55.84 | 3.05 | 32.49 | 32.63 | 84.63 | 5.13 |

| 2. | 70:30 | 15 | 250 | 130 | 53.52 | 5.29 | 34.5 | 34.9 | 81.28 | 8.71 |

| 3. | 90:10 | 20 | 250 | 130 | 55.98 | 2.89 | 32.01 | 32.14 | 84.84 | 4.66 |

| 4. | 70:30 | 20 | 250 | 130 | 53.55 | 5.17 | 33.55 | 33.94 | 81.23 | 8.04 |

| 5. | 90:10 | 15 | 450 | 130 | 57.2 | 2.35 | 31.45 | 31.53 | 85.72 | 3.39 |

| 6. | 70:30 | 15 | 450 | 130 | 54.02 | 4.18 | 33.32 | 33.53 | 82.84 | 7.2 |

| 7. | 90:10 | 20 | 450 | 130 | 57.35 | 2.23 | 31.12 | 31.99 | 85.9 | 3.02 |

| 8. | 70:30 | 20 | 450 | 130 | 54.3 | 4.01 | 32.54 | 32.78 | 82.97 | 6.4 |

| 9. | 90:10 | 15 | 250 | 170 | 53.81 | 4.86 | 33.05 | 33.4 | 81.63 | 7.44 |

| 10. | 70:30 | 15 | 250 | 170 | 51.87 | 7.42 | 35.98 | 36.73 | 78.34 | 11.62 |

| 11. | 90:10 | 20 | 250 | 170 | 53.72 | 4.76 | 34.12 | 34.45 | 82.05 | 8.14 |

| 12 | 70:30 | 20 | 250 | 170 | 51.39 | 7.38 | 35.43 | 36.19 | 78.23 | 11.58 |

| 13. | 90:10 | 15 | 450 | 170 | 54.17 | 4.21 | 32.02 | 32.29 | 82.5 | 6.36 |

| 14. | 70:30 | 15 | 450 | 170 | 51.86 | 5.89 | 34.96 | 35.45 | 80.43 | 10.35 |

| 15. | 90:10 | 20 | 450 | 170 | 54.32 | 3.79 | 32.98 | 33.19 | 83.44 | 6.69 |

| 16. | 70:30 | 20 | 450 | 170 | 51.9 | 5.62 | 34.54 | 34.99 | 80.75 | 9.97 |

| 17. | 100:0 | 17.5 | 350 | 150 | 59.13 | 2.02 | 28.68 | 28.75 | 85.97 | 0 |

| 18. | 60:40 | 17.5 | 350 | 150 | 53.76 | 6.42 | 33.54 | 34.14 | 79.16 | 8.47 |

| 19. | 80:20 | 12.5 | 350 | 150 | 52.58 | 5.12 | 34.72 | 35.09 | 81.61 | 9.43 |

| 20. | 80:20 | 22.5 | 350 | 150 | 53 | 4.98 | 33.45 | 33.81 | 81.53 | 8.31 |

| 21. | 80:20 | 17.5 | 150 | 150 | 53.02 | 5.05 | 34.88 | 35.24 | 81.76 | 9.21 |

| 22. | 80:20 | 17.5 | 550 | 150 | 54.83 | 3.03 | 32.81 | 32.94 | 84.72 | 6.04 |

| 23. | 80:20 | 17.5 | 350 | 110 | 55.32 | 2.04 | 32.57 | 32.63 | 86.41 | 5.44 |

| 24. | 80:20 | 17.5 | 350 | 190 | 50.02 | 6.23 | 35.26 | 35.8 | 79.97 | 12 |

| 25. | 80:20 | 17.5 | 350 | 150 | 52.15 | 4.67 | 34.12 | 34.43 | 82.2 | 9.23 |

| 26. | 80:20 | 17.5 | 350 | 150 | 52.15 | 4.67 | 34.12 | 34.43 | 82.2 | 9.23 |

| 27. | 80:20 | 17.5 | 350 | 150 | 52.15 | 4.67 | 34.12 | 34.43 | 82.2 | 9.23 |

| 28. | 80:20 | 17.5 | 350 | 150 | 52.15 | 4.67 | 34.12 | 34.43 | 82.2 | 9.23 |

| 29. | 80:20 | 17.5 | 350 | 150 | 52.15 | 4.67 | 34.12 | 34.43 | 82.2 | 9.23 |

| 30. | 80:20 | 17.5 | 350 | 150 | 52.15 | 4.67 | 34.12 | 34.43 | 82.2 | 9.23 |

R = Broken Rice A = Apricot

The colour parameter L* (luminosity) varied from 50.02 to 59.13, the brightness value decreased with addition of apricot powder. The decrease in lightness of the extrudates with apricot powder addition is as a result of non-enzymatic browning promoted by the sugar in the added material and degradation of the pigment (9-10]. Barrel temperature had a significant effect on L* value of extrudates. L* value decreased with increase in temperature as higher temperatures promoted non-enzymatic browning and pigment destruction. Increase in screw speed resulted in increase in brightness due to low retention time in extruder. Redness and yellowness were in range of 2.02 to 6.2 and 28.68 to 35.98 respectively. The addition of apricot powder resulted in increase in both a* and b* values due to the presence of carotenoids. Increase in temperature resulted in increase in a* and b* value due to browning caused by pigment decomposition or caramelisation of sugars at high temperature of extrusion [11]. Increase in screw speed resulted in lower a* and b* value as screw speed is inversely related to the residence time in extrusion, and degree of fill of extruders [12]. High moisture content results in higher L* and lower a* and b* value due to low melt temperature and viscosity resulting in minimum destruction of pigments as extrusion is less destructive [13-14]. The Chroma indicates saturation, and is directly proportional to the intensity of the colour and increase in apricot powder shows high Chroma values due to presence of carotenoids. The hue angle is used as a colour quality parameter in processed foods and, on the Hunter colour space, a value of 0º or 360º represents red, 90 º represents yellow, 180 º represents green, and 270 º represents blue. Hue angle ranged from 79.16 to 85.97. The total difference in colour values (ΔE) increased with temperature and composition, where as high moisture and screw speed resulted in low ΔE.

L* = 52.13 – 1.28C + 0.38S – 1.22T – 0.12CS + 0.12CT – 0.16ST + 1.09C2 +1.8M2 + 0.46S2 + 0.15T2 (1)

a* = 4.67 + 1.07C – 0.52S + 0.96T – 0.16CS – 0.078C2 + 0.13M2 – 0.12S2 – 0.099T2 (2)

b* = 34.12 + 1.05C – 0.17M – 0.51S + 0.73T – 0.24CM + 0.23MT – 0.73C2 (3)

CR = 34.43 + 1.15C – 0.14M – 0.55S + 0.82T – 0.29CM + 0.20CT + 0.17MT – 0.71C2 (4)

Hue angle = 82.20 – 1.59C + 0.76S – 1.46T + 0.22CS – 0.21M2 + 0.20S2 + 0.19T2 (5)

∆E = 9.23 + 1.92C – 0.16M – 0.76S + 1.61T – 0.13CM + 0.18MT – 1.24C2 – 0.39S2 – 0.12T2 (6)

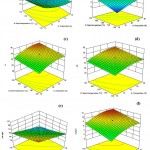

The models developed for the lightness (L*), redness (a*), yellowness (b*), chroma, hue angle and total colour change (∆E) of rice flour apricot extrudates as functions of independent variables are shown in equations 1 to 6. The models of colour parameters (equation 1-3) show quadratic effect with composition. Apricot powder level had a negative significant linear effect on L value, whereas it had a positive significant effect on a*, b* values. The positive coefficients of linear terms of composition, barrel temperature and negative coefficients of screw speed (equations 2-5) indicated that a* (redness), b* (yellowness), CR (chroma), hue angle and total colour change increased with increase in barrel temperature, composition and decreased with decrease in screw speed. The extrudates obtained at 190oC with 20% apricot level were least bright and those obtained at 150oC with 0% apricot powder were most bright. Multiple regression analysis models of hunter colour parameters, hue angle, chroma and total colour change were significant and the lack of fit of the models of colour parameters were not significant (Table 2). The predicted R-square and adjusted R-square were in reasonable agreement with each other. Fig 1(a), Fig.1(b), Fig.1(c), Fig.1(d), Fig.1(e) and Fig.1(f) shows the L*, a*, b*, chroma, hue angle and ∆E as a function of temperature and composition .

Table 2: ANOVA and model statistics for the colour parameters of rice based apricot incorporated extruded snacks

| Response to models | ||||||

| Term | L* | a* | b* | Chroma | Hue angle (o) | ∆E |

| F-Value | 275.14 | 154.76 | 66.58 | 54.05 | 103.40 | 286.91 |

| P>F | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| Mean | 53.65 | 4.53 | 33.49 | 33.84 | 82.37 | 7.77 |

| Standard deviation | 0.17 | 0.16 | 0.26 | 0.31 | 0.30 | 0.23 |

| CV | 0.32 | 3.62 | 0.78 | 0.92 | 0.37 | 2.94 |

| R-square | 0.9961 | 0.9931 | 0.9842 | 0.9806 | 0.9897 | 0.9963 |

| Adjusted R square | 0.9925 | 0.9867 | 0.9694 | 0.9624 | 0.9802 | 0.9928 |

| Predicted R square | 0.9777 | 0.9604 | 0.9088 | 0.8880 | 0.9409 | 0.9786 |

| Adequate precision | 71.907 | 45.248 | 37.148 | 34.678 | 36.689 | 71.382 |

| Lack of fit | NS | NS | NS | NS | NS | NS |

|

Figure 1: Response surface plot of: (a) L* (b) a* (c) b* (d) chrome (e) hue angle (f) ∆E as a function of a barrel temperature and composition.

|

Conclusion

Regression result revealed dominant effect of apricot powder level on hunter colour parameters (L*, a*, b*), chroma, hue angle and total colour change of extrudates followed by barrel temperature. The effect of composition, screw speed and temperature was found to be linear on all colour parameters. Moisture content had an effect on all colour parameters except hue angle which showed quadratic effect with moisture content. High screw speed, high moisture content and low barrel temperature resulted in higher L* value due to minimal degradation of pigments.

References

- Brennan, M. A., Derbyshire, E., Tiwari, B. K., and Brennan, C. S. Ready-to-eatsnack products: the role of extrusion technology in developing acceptable and nutritious snacks. J. Food Sci. Technol. 2013; 48: 893-902

CrossRef - Ding, Q.B., Ainsworth, P., Plunkett, A., Tucker, G., Marson, H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. Food. Eng. 2006; 73: 142-148.

CrossRef - Cheftel, J.C. Nutritional effects of extrusion-cooking. Food Chem.1986; 20 : 263-283

CrossRef - Bisharat, G. I., Oikonomopoulou, V. P., Panagiotou, N. M., Krokida, M. K., Maroulis, Z. B. Effect of extrusion conditions on the structural properties of corn extrudates enriched with dehydrated vegetables. Food Res. Int. 2013; 53: 1–14.

CrossRef - Obradovic, V., Babic, J., Šubaric , D., Ackar, D., Jozinovic, A. Improvement of nutritional and functional properties of extruded food products. Food Nutr. Res. 2014; 53: 189–206.

- Altan, A., McCarthy, K.L., Maskan, M. 2008. Twin-screw extrusion of barley-grape pomace blends: Extrudate characteristics and determination of optimum processing conditions. Food Eng. 2008; 89: 24-32.

CrossRef - Jorge, M., Roberto, G., Karina, P.J.X., Oliva, C.E., Benjamin, R. Cuauhtemocc, R. 2006. The optimization of the extrusion process when using maize flour with a modified amino acid profile for making tortillas. J. Food Sci. Technol. 2006; 41: 727-736.

CrossRef - , Approved Laboratory Methods, St. Paul Minnesota, USA, 2000

- Gui, Y., Ryu, G. H. Effects of extrusion cooking on physicochemical properties of white and red ginseng (powder). Gins. Res. 2014; 38(2): 146–153.

CrossRef - Selani, M. M., Canniatti Brazaca, S. G., Santos Dias, C. T., Ratnayake, W. S., Flores, R. A., Bianchini, A. Characterisation and potential application of pineapple pomace in an extruded product for fibre enhancement. Food Chem. 2014; 163: 23–30.

CrossRef - Hagenimana, V., Carey, E. E., Gichuki, S. T., Oyunga, M. A., Imungi, J. K. (1999). Carotenoid contents in fresh, dried and processed sweetpotato products. Food Nutr.1999; 37: 455–473.

- Mahasukhonthachat, K., Sopade, P. A., Gidley, M. J. (2010). Kinetics of starch digestion and functional properties of twin-screw extruded sorghum. Cereal Sci 2010; 51: 392–401.

CrossRef - Okarter, N., Liu, C.S., Sorrells, M. C., Liu, R. H. Phytochemical content and antioxidant activity of six diverse varieties of whole wheat. Food Chem. 2010; 119: 249–257

CrossRef - Riaz, M. N., Asif, M., Ali, R. Stability of vitamins during extrusion. Rev. Food Sci. Nutr. 2009; 49: 361–368.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.