Manuscript accepted on :

Published online on: 19-12-2015

Using Rapid Prototyping Technologies for Creating Implants with Cellular Structure

Polina Nikolaevna Kilina1 , Vladimir PavlovichVasilyuk2 , Evgeniy Aleksandrovich Morozov1, Almaz Mullayanovich Khanov1 and Lyudmila Dmitrievna Sirotenko2

1Perm National Research Polytechnic University, Russia, 614990, Perm, Komsomolskyprospekt, 29 2Perm State University of Medicine named after Academician E.A.Wagner Russia, 614990, Perm, Petropavlovskayastreet, 26

ABSTRACT: The paper presents the results of using rapid prototyping technology for obtaining implants that consist of Wigner-Seitz cellular structures. Using the method of stereolithography, prototypes from EnvisionTec SI 500 photopolymer were obtained at the EnvisionTec Perfactory Xede installation; 200 watts gas (CO²) laser was used in the process. The possibility of creating cellular materials with complex spatial structure has been shown. Laser sintering was performed at the Realizer SLM 50 installation, and argon was used for protective atmosphere in the working chamber. A 250 W 680 nm fiber laser was used in the process. The source material was 316L stainless steel powder. Sintering was performed on a steel substrate with radiation intensity of 1,500 mA and 60 μs exposure time. Implants were obtained in the form of cells and tubes filled with cells that were implanted into outbred rats at the base of tail. Six months observation of the animals did not reveal rejection of implants, and the integral indicators (behavior, appetite, temperature reaction) were in the normal range. A 3D model of jaw implant was created using the Delcam Power Shape software suite. Initial material in the experiment was titanium powder with particle of an average size of 30 μm, which had the shape close to spherical. Samples were sintered at intensities of radiation of 1,000 mA, 1,400 mA, and 1,700 mA. In order to reduce samples manufacturing time while maintaining integrity of the Wigner-Seitz cell structure without thinning walls, layer dissection distance of 0.1 mm was chosen.

KEYWORDS: 3D model; rapid prototyping; selective laser sintering; Wigner-Seitz cell; mesh implants; metal powders

Download this article as:| Copy the following to cite this article: Kilina P. N, Vasilyuk V. P, Morozov E. A, Khanov A. M, Sirotenko L. D. Using Rapid Prototyping Technologies for Creating Implants with Cellular Structure. Biosci Biotech Res Asia 2015;12(2) |

Introduction

Currently in medical practice, in reconstructive plastic surgery in particular, innovative technologies are intensively used for reconstruction of bone defects by making individual medical implants, creating supporting structures for dental prostheses in dentistry, plates for maxillofacial surgery (Semkin, 2000), (Tverskoy, 2012). For this purpose, various biocompatible materials (titanium and its alloys, zirconium ceramics, polymeric materials, etc.) are used (Mazzoli, 2013).

The rapid prototyping method (Nazarov, 2011) is used to produce both single prototypes and small production quantities. The time of forming the finished product depends on the size of the sample and not on its complexity. The technology can be used for layer-by-layer synthesis of parts with properties that can be unique for certain type of products, such as improved mechanical characteristics, homogeneous structure. The method makes it possible to fully use computer-aided design (CAD) software in combination with laser technology for synthesis of 3D products (Nazarov, Okounkova, 2012). When making structural changes in a part, or during development of several standard sizes, only the 3D model of the part is changed, rather than the technological process, which reduces production time.

One of the most effective methods that make it possible to obtain products of complex spatial structure from a wide range of materials is selective laser sintering (Capel et al., 2013). Manufacturing of similar structures with other methods (substrative or formative) is difficult, due to complex spatial geometry of samples and the presence of cellular structures. As a result of substrative processing (mechanical, electric corrosion and others), elementary quantities of material are removed from the surface. The formative method is in making the shape of the product without removing layers of material from the initial workpiece. It includes surface plastic deformation, plastic working, molding, etc. Products obtained with the help of additive technologies in the majority of cases require neither further mechanical processing, nor designing additional technological tooling. The geometry of the model unambiguously defines the process of updating it, there cannot be many variants in processing, and the influence of human factor is limited, as well as accumulation of discrepancies, as compared to traditional technological processes (Walter, 2011)

The essence of the method lies in the fact that under the action of powerful laser radiation, the powder is sintered layer-by-layer in accordance with the original 3d model that is prepared using various CAD systems (Miller, 2003). The powder material is applied to special substrate (titanium, aluminum, steel, etc.) and is leveled with a scraper; the particles ablate or completely melt under heat action of laser radiation. As a result, the particles solidify, forming a fused or sintered structure, the substrate is lowered one level down and the process repeats. The sample is formed in the layer of powder material, thus minimizing the number of supports required for defect-free formation of the product. The excess of the powder may be reused after sieving. Inert gas or vacuum is used as protective atmosphere, which is chosen depending on powder material (Gibson, 2009), (Gibson, 2010).

Properties of highly porous cellular structures depend on both initial material (inherited defects may occur) and geometric structure, and on the method of obtaining as well. When the melt is foamed with gas, and in case of suspension duplication of the polymer matrix, uneven and unregulated porous structure may occur (content and size of pores). As a result of using the technological scheme of producing metal foams from metal powders and porofors, the following shortcomings may be identified: limited number of systems, and the problem of choosing the porofor – the temperature of its decomposition must be a little lower than the temperature of metal melting. When the melt is formed with removable solid porofor, the difficulty in its extraction usually occurs. Compared to traditional methods (Antsiferov, Porozova, 1996) of obtaining highly porous cellular materials, the method of selective laser sintering is dominating for creating materials with regulated structure.

The aim of this work was the use of methods of rapid prototyping for creating implants that consist of cells of regular geometrical shape out of various materials (photo-polymer, steel and titanium powders) for replacing bone defects. The goals of the experimental study included:

- developing a computer 3D model of the samples with cellular structure of Wigner-Seitz;

- updating prototypes out of photo-polymer SI 500 according to the technology of laser stereolithography;

- selective laser sintering of implants out of stainless steel 316 L powder;

- implanting the obtained samples to outbred rats close to tail base; and

- selecting modes of laser sintering and manufacturing draw titanium implants.

Methods

The implants are based on 2 mm cells with 0.05 mm walls, representing a region of space centered at some point of the Bravais lattice, which is closer to this point of the lattice than to any other point (Figure 1). The smallest volume area delimited by planes is a Wigner-Seitzcell (Ashcroft, 1979).

|

Figure 1: An elementary Wigner-Seitz cell |

For manufacturing an implant with Wigner-Seitz cell structure, we used the technology of stereo lithography (Stereolithoqraphy-SLA) (Kumar, Kruth, 2010). In the initial phase, the implants were obtained from the EnvisionTec SI 500 photo-polymer on the installation for fast prototyping EnvisionTec Perfactory Xede EnvisionTec Perfactory Xede with the working area size of 220×280×380 mm. A 200 W gas (СО²) laser was used in the process.

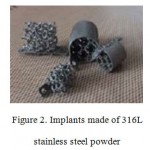

Metallic samples for implanting into animals were grown at an installation for selective laser sintering Realizer SLM 50 with the development area size Ø 70×35 mm. A 250 W 680 nm fiber laser was used in the process. The protective atmosphere of the working zone was argon, and pressure of 8 mBar was maintained in the chamber. The initial material for obtaining samples was stainless steel powder AISI 316 L with average particle size of 30 µm. Steel has high corrosion and heat resistance up to 600 degrees, sufficient ductility, and is characterized by the absence of magnetic properties. The particles were sintered on a steel substrate with intensity of radiation of 1,500 mA, the time of exposure was 60 µs. The implants were formed in the shape of Wigner-Seitz cells, and in the shape of tubes filled with cells (Figure 2).

|

Figure 2: Implants made of 316L stainless steel powder |

Further research was performed on the basis of the Central Scientific and Research Laboratory of the State Budgetary Institution of Higher Professional Education of the Perm State Medical University named after Academician E. A. Wagner of the Ministry of Health of the Russian Federation. The implants were implanted into the base of tail in 5 outbred rats is the age between two and three months, weighing between 350 and 400 grams, with body length, including the tail, between 23 and 25 cm. All experiments were performed in accordance [Annex to the Order of the Ministry of Health of the USSR dated 12.08.1977. No. 755] with the “European Convention for Protection of vertebrate animals used for experiments and other scientific purposes” dated March 18, 1986 (The text was modified in accordance with the provisions of the Protocol (ETS # 170), after it came into force on December 2, 2005; the Lisbon Treaty amending the Treaty about the European Union and the Treaty establishing the European Community came into force on December 1, 2009).

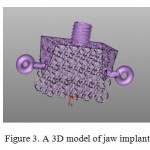

The next stage of the research was preparing a jaw implant for implanting into a rabbit. A 3D model of the sample was prepared with the use of the Delcam PowerShape software suite, and all objects were solid and sheet bodies. The model was an array with dimensions of 6 ×10 × 8 mms, consisting of elementary Wigner-Seitz cells with the cell size of 2 mm, and wall thickness of 0.05 mm (Figure 3). The design also contained elements for fixation of the implant. The model was sectioned into layers in the Magics software package, and a file of the model and supports was created in the *.f and s format.

|

Figure 3: A 3D model of jaw implant |

4 possible indentations were selected for sectioning the model into layers of 0.05; 0.1; 0.15; 0.2 mm. In case of indentations equal to 0.15 and 0.2 mm, the walls contour of Wigner-Seitz cells was completely filled, which increases the time of growing samples. If the indentation of layer sectioning is more than 0.2 mm, the structure of cells becomes distorted. The indentation is 0.05 mm and less, the time of manufacturing is reduced, but the walls become thinner, which may lead to insufficient durability of the structure. The layer sectioning indentation value equal to 0.1 mm was chosen in order to preserve structural integrity of the cells with reduced time of manufacturing (Figure 4).

Initial material in the experiment was titanium powder with particle of an average size of 30 μm, which had shape close to spherical (Figure 5).

|

Figure 4: Model layers sectioning with a plane with 0.1 mm |

|

Figure 5: Particles of titanium powder |

The powder was studied using an inverted top light microscope Olympus GX 51 with magnification 200. The particles of the powder were sintered on a titanium and steel substrate, and various parameters of laser radiation were used. The thickness of the processed layer was 30 µm, and time of exposure was 60 µs. Sintering occurred at intensities of radiation of 1,000 mA, 1,400 mA, and 1,700 mA.

Results

On the basis of earlier implemented program of computer visualization of bone defect (Vasilyuk 2014), which consisted in creating a digital three-dimensional image according to computer tomography data, the size of the defect was defined, as well as borders of the resection planned. The 3D image was transferred into the STL format, and computer modeling was performed for the will-be implant with cellular structure that completely matches the defect of the bone. With the use of technology of stereolithography, a prototype was manufactured from the SI 500 photopolymer with correct geometrical structure, consisting of Wigner-Seitz cells. The possibility of creating cellular materials with complex spatial configuration has been shown. Using the method of selective laser sintering on a steel substrate, samples of implants were obtained from stainless steel AISI 316 L. For processing steel powder, the following amounts of sintering were selected: intensity of radiation was 1,500 mA, time of exposure was 60 µs, and the speed of laser beam scanning was 500 mm per second. The obtained samples were implanted into 5 outbred rats, close to the base of their tails. After implanting, the general state of the animals was assessed for half a year, using integral indicators (behavior, appetite, and temperature reaction) and tail tissues local reaction was assessed for the surgical interference. In course of observing the animals, it was found that they were active, their temperature reaction was normal, and their appetite was not affected. The local and general reaction to the implant was manifested only at the beginning of the experiment (8 to 10 days). In the locations of samples implanting in the rats’ tails area, pink scars are visualized on the skin, and no rejection of the implant is observed.

With the help of Delcam PowerShape software suite, a 3 D model of a draw implant was formed. In order to reduce samples manufacturing time while maintaining integrity of the Wigner-Seitz cell structure without thinning connection elements, layer dissection distance of 0.1 mm was chosen. The following modes were considered for processing titanium powder: time of exposure – 60 µs, speed of laser beam scanning – 500 mm per second; in the process three intensities of radiation were studied with I=1,000 1,400 and 1,700 mA. Various materials for the substrate were also considered for layer-by-layer synthesis of products. In course of sintering particles of titanium powder on a titanium substrates, it was found that intensity of radiation I=1,000 mA was insufficient for uniform structure of the particles and preserving the shape, sintering was not complete, and the samples exfoliated. The current with I=1,400 mA was not enough for sufficient adhesion of the titanium particles to the substrate, each layer sequentially peeled off the titanium base (Figure 6). The same effect was observed in sintering on a steel substrate with radiation intensity of I=1,000 1,400 and 1,700 mA; the layers of the material peeled off due to insufficient adhesion. The full-fledged formation of the implant occurred in case of laser beam intensity I=1,700, with time of exposure 60 μs. As a result, a sample was obtained with regulated cellular structure; the total time of manufacturing was 2 hours and 30 minutes (Fig. 7)

|

Figure 6: Sample peeling off |

|

Figure 7: a), b) Cellular jaw implant |

Discussion

Reconstructive plastic surgery is related to introducing foreign bodies into the tissues of the organism, and in manifestations of tissue reaction to their material (Syam, 2011), (Beglaryan, 2011). The material of the implant should cause necessary reaction of the tissue that would ensure its efficient acceptance and formation of healthy bone tissue. In this regard, materials for implants are to meet a number of requirements: non-toxicity, biological compatibility, absence of immunological rejection, availability of adhesion surface and the optimal size of pores for unhindered proliferation of osteoblasts in implant cells. The most frequently used material in implant dentistry is titanium and its alloys, due to its high durability and corrosion resistance. These materials do not change their properties in interaction with aggressive biological environments of the organism and do not cause toxic influence on live tissues, thus they fully meet requirements for implants (Hench, Johnes, 2007), (Mullen et al., 2010), (Pattanayak et al., 2011). In addition, the corrosion resistance is observed in austenitic steel AISI 316 L, which is actively used in surgical and medical industry; however, it is characterized by insufficient resistance in case of direct contact with biological environments. This problem can be solved by adding various biologically compatible materials, for example, hydroxyapatite, for increasing osteoconductive and osteoinductive properties (Hao et al., 2009).

Availability of the developed regulated surface structure of the implant is an important aspect in growing the bone tissue, resulting in biological fixation of the implant. This work is focused on the use of Wigner-Seitz cells in the structure of the implant, with cell size of 2 mm, and wall thickness of 0.05 mm. In addition, variants were considered for creating samples with pore size between 0.5 to 1 mm (Vasilyuk, 2014). It is assumed that a structure with increased cell size would make it possible to achieve earlier osseointegration, due to freer proliferation of osteoblasts into cells of the implant. The vertebrae and the jaw consist of a lamellar bone tissue formed on the outside of a cortical layer of compact bone tissue, and on the inside of spongy bone tissue formed by bone plates, between which red bone marrow is located (Kuznetsov, 2007). The similarity of histological structure of jaws and vertebra makes it possible to introduce the implant into the area close to the base of tail. Creating cellular materials with regulated structure, and results of introducing implants into the area close to the base of animals tails, make it possible to conclude that the positive result is promoted not only by the kind of material but by the structure and design of the implant, as well.

Modeling loads and tensions experienced by the implant in the exploitation (loads from surrounding bone tissue, loads from the free surface of the implant) would allow full assessing of the applicability of this structure. The behavior of cellular materials is described by mechanics of solids. Theoretical models of mechanical behavior of this class of materials make it possible to calculate physical and mechanical constants of the material, and to define the areas of tensions concentration and deformation mechanisms that precede destruction of the cellular material. Calculation of the implant design response to external influence, and modeling various states of cellular materials would allow to forecast effective values of external destructive pressure and the modulus of elasticity of the cellular material.

Along with quality requirements that are applicable to the initial materials, and geometrical composition of highly porous cellular structures, their properties depend on methods of obtaining as well. The technology of selective laser sintering makes it possible to make an implant that would repeat the form of the replaced organ with high degree of accuracy. The most important parameters that define the quality of sintered layers and, consequently, of the whole sample are the characteristics of the initial materials and parameters of sintering. The characteristic of initial materials include size and shape of particles, their bulk density and the specific surface area of the powder. The parameters of sintering are intensity of laser radiation, time of exposure, power of the laser, speed of scanning, and frequency of pulses. The quality of sintered layers is characterized by the maximum achievable accuracy, uniform density, maximum and minimum thickness of the processed layer. Also an important role is played by the protective atmosphere, especially when working with titanium, due to its chemical reactivity. An important stage is the selecting of the optimum parameters of processing, both experimentally and by the methods of mathematical modeling (Grishaev, 2011), which would make it possible to improve the process of creating materials with predefined set of requirements (Bagatov, Zakharov, 2011).

Conclusion

The present work shows the possibility of creating cellular materials with a complex spatial structure, using the technologies of rapid prototyping that would make it possible to reproduce an implant with high degree of accuracy. Due to design peculiarities related to the complex structure of the internal channels of the samples, their manufacturing by subtractive and formative methods is rather difficult. The additive technologies, such as selective laser sintering and the method of stereolithography made it possible to obtain modeled structures with a predefined degree of accuracy.

On the basis of computer software for 3D visualization of defects, computer modeling of an implant was made; the implant matches the defect, and is a geometrical structure of Wigner-Seitz cells. With the help of laser stereolithography, prototypes of implants were grown from SI 500 photo-polymer. For further research, implants were obtained from stainless steel 316L using the method of layer-by-layer laser sintering, in the shape of cells and in the shape of tubes filled with cells. The samples were implanted into 5 outbred rats and fixed close to the base of their tails. The similarity of histological structure of jaws and vertebra makes it possible to introduce the implant into the area close to the base of tail. The animals were observed for half a year in dynamics, and this made it possible to conclude that the cellular structure of the implant of a certain size contributed to faster growing of bone tissue into the implanted product. No local complications or implant rejection in healing of surgical wounds were observed; the general reaction of animals’ organism was absent. Further studies would make it possible to determine the influence of cell size on the mechanism of bone tissue growing into the cells of the implant.

With the help of the Delcam Power Shape CAD system, a 3D model of draw implant was created. Titanium implants with Wigner-Seitz cell structure with cell size of 2 mm and wall thickness of 0.05 mm were obtained on an installation for selective laser sintering Realizer SLM 50. It was found that intensity of radiation I=1,000 and 1,400 mA was insufficient for obtaining uniform structure of the particles, preserving the shape, and ensuring stability of the process of layer-by-layer product formation. Laser sintering of particles was observed with current I=1,700 mA. It was found that the layer sectioning indentation value equal to 0.1 mm makes it possible to preserve structural integrity of the cells with reduced time of manufacturing.

The use of implants consisting of Wigner-Seitz cellular structures may be a promising area in reconstructive plastic surgery. Since this study is in the stage of creating implants with a structure consisting of Wigner-Seitz cells, we cannot consider the process fully studied within the framework of this work. Mechanical testing of the obtained samples and implantation of jaw implants into animals is planned. Modeling of influence behavior in the process of exploitation will make it possible to fully assess applicability of this structure. The results shown in this paper are the basis for further research and development, aimed at improving the process of obtaining implants consisting of regulated cellular structures, using the methods of fast prototyping.

Acknowledgments

* The research was sponsored by the Ministry of Education and Science, according to the state assignment (basic part) # 2014/152 R&D # 1460

References

- N.,& Porozova S.E. (1996). Highly porous cellular materials. Perm: Perm Publishing House State Technical University, pp: 207.

- Ashcroft, N., & Mermin N. (1979). Physics of solids (Vol.1, pp. 399). Moscow: Mir.

- Bagmutov, V.P., & Zakharov, I.N. (2011). Modeling of thermal processes in case of surface treatment of inhomogeneous metallic bodies with high temperature moving pulse source. Computational Mechanics of Solids,Vol. 4, 1, 5-16.

- Beglaryan, V.V. (2011). Clinical and experimental study of the use of dental implants with through porosity. (Thesis of Candidate of Medical Sciences). Samara State Medical University, Samara.

- Walter, A.V. (2011). Layer-by-layer synthesis of reinforced 3D products. Mining engineering: collection of materials. Mining Information and Analytical Bulletin (scientific and technical journal), Vol. 2, 12, 222-229.

- Vasilyuk, V.P., Straub, G.I., Kachergus, S.A., Kosarev, P.V., & Asanovich, M.O. (2014). Experimental justification of using innovation of technologies in manufacturing implants with cellular structure for replacing bone defects in facial skeleton (preliminary results). Family Health – 21st century, 2, 42-54.

- Grishaev, R.V., Mirzade, F.H., & Khomenko, M.D. (2011). Numerical modeling of microparticles melting kinetics in case of selective laser sintering. Promising Materials, 10, 135-142.

- Kuznetsov, V.E. (2003). Systems for rapid manufacturing of prototypes in their extensions. CAD/CAM/CAE, 4,2-7.

- Kuznetsov, S.A., &Mushkabarov, N.N. (2007).Histology, Cytology and Embryology: a textbook for medical schools (pp. 600). Moscow: LLC Medical information Agency.

- Kuznetsova, D.S., Timashev, P.S., Bagratashvili, V.N., & Zagaynova, E.V. (2014). Bone implants based on scaffolds and cellular systems in tissue engineering (Review). Modern Technologies in Medicine, Vol. 6, 4, 201-212.

- Nazarov, A.P. (2011). The perspectives of rapid prototyping by selective laser melting/sintering. Bulletin of MSTU “Stankin”, 4(16), 46-51.

- Nazarov, A.P., & Okounkova, A.A. (2012). Typical samples of products obtained by the method of selective laser sintering. Bulletin of the SSTU, 3(67), 76-83.

- Semkin, V.A., Shamsudinov, A.G., & Lishev, I.N. (2000). The results of using power titanium plates for replacing defects in the lower jaw. Proceedings of the IV all-Russian Scientific and Practical Conference: Actual Problems of Dentistry (pp. 135-137).Moscow, March 22 – 30, 2000.

- Tverskaya, M.M., Petrova, L.N., Aladin, A.S., Sulatskaya, E.Y., &Zharinova, A.S. (2012). Computer technology for manufacturing implants using by the method of layer-by-layer laser sintering. Bulletin of the South Ural State University, 23(16), 64-69.

- Khanov, A.M., Sirotenko, L.D., Matygulina, E.V., Samusev, I.V., & Bashkirtsev, G.V. (2010). Predicting physical and mechanical properties of high-porous permeable cellular materials on the basis of structural modeling. Bulletin of PNRPU. Mechanical engineering. Materials science, 1, 17-29.

- Hench, L., &Jones, J. (2007).Biomaterials, artificial organs and tissue engineering (pp. 304). Moscow: Technosphera.

- Capel, A.J., Edmondson, S., Christie, S.D., Goodridge, R.D., Bibb, R.J., & Thurstans, M. (2013) Design and additive manufacture for flow chemistry. Lab Chip, 13(23), 4583– 4590.http://dx.doi.org/10.1039/c3lc50844g

- Gibson, I., Rosen, D.W., & Stucker, B. (2009).Additive manufacturing technologies. Rapid prototyping to direct digital manufacturing. New York, USA: Springer.

- Gibson, D.,Rosen W., &Stucker, B. (2010).Additive Manufacturing Technologies: rapid prototyping to direct digital manufacturing(Ch. 9, pp. 237-258). NewYork: Springer. ISBN 978-1-4419-1119-3

- Hao, L., Dadbakhsh, S., Seaman, O., & Felstead, M. (2009).Selective laser melting of a stainless steel and hydroxyapatite composite for load-bearing implant development. Journal of Materials Processing Technology, 209(17), 5793-5801.

- Kumar, S., &Kruth, J.P. (2010) Composites by rapid prototyping technology. Materials & Design, Vol. 31, 2, 850-856.

- Mazzoli, A. (2013). Selective laser sintering in biomedical engineering. Medical & Biological Engineering & Computing, 51(3), 245–256. http://dx.doi.org/10.1007/s11517-012-1001-x.

- Mullen, L., Stamp, R.C., Fox, P., Sutcliffe, C.J., Jones, E., Ngo, C. (2010). Selective laser melting: a unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. II. randomized structures. Journal of Biomedical Materials Research – Part B Applied Biomaterials, 92(1), 178-188.

- Pattanayak, D.K., Matsushita, T., Kokubo, T., Fukuda, A., Takemoto, M., Fujibayashi, S., Nakamura, T., Sasaki, K., &Nishida, N. (2011). Bioactive Ti metal analogous to human cancellous bone: fabrication by selective laser melting and chemical treatments. Acta Biomaterialia, 7(3), 1398-406. doi: 10.1016/j.actbio.2010.09.034.

- Syam, W.P., Mannan, M.A., &Al-Ahmari, A.M. (2011).Rapid prototyping and rapid manufacturing in medicine and dentistry. Virtual and Physical Prototyping, 6(2), 79-109.

This work is licensed under a Creative Commons Attribution 4.0 International License.