Manuscript accepted on : 05 December 2016

Published online on: --

Plagiarism Check: Yes

Effect of Garlic Essential oil on Performance of Rice Bran oil During Deep Fat Frying

Shafat Khan, Proshanta Guha and Amaresh

Department of Agricultural and Food Engineering Indian Institute of Technology Kharagpur.

Corresponding Author E-mail: shafat.khan43@iitkgp.ac.in

DOI : http://dx.doi.org/10.13005/bbra/2467

ABSTRACT: Deep fat frying involves immersion of food in hot edible oil at a temperature above the boiling point of water for a given period of time the process involves both heat and mass transfer. In this study deep fat frying with pure Rice bran oil (control) as well as rice bran oil blended with different concentrations of garlic essential oil was carried out. The physicochemical analysis of the Rice bran oil obtained after each batch of frying was carried out followed by FTIR analysis. Peroxide values, Free Fatty Acid content, viscosity, oryzanol content of rice bran oil and color values were also analyzed. The results showed a slightly higher level of degradation of pure rice bran oil compared to the blended Rice bran oil during deep fat frying. FTIR analysis also revealed the same trend as there was not much difference in the graph obtained except for the higher transmittance in case of the pure rice bran oil depicting a slightly higher level of degradation compared to the blended one. It may be concluded that Rice bran oil is stable oil good for deep fat frying and addition of garlic essential oil as a natural antioxidant enhances the stability of the oil during frying.

KEYWORDS: FTIR Rice bran oil; peroxide value; free fatty acid; viscosity; oryzanol ;

Download this article as:| Copy the following to cite this article: Khan S, Guha P, Amaresh A. Effect of Garlic Essential oil on Performance of Rice Bran oil During Deep Fat Frying. Biomed Pharmacol J 2017;10(1) |

| Copy the following to cite this URL: Khan S, Guha P, Amaresh A. Effect of Garlic Essential oil on Performance of Rice Bran oil During Deep Fat Frying. Biomed Pharmacol J 2017;10(1) Available from: https://www.biotech-asia.org/?p=20465 |

Introduction

Allium sativum L.,commonly known as garlic, belongs to the onion family Alliaceae and is closely related to the onion, shallot, leek, chive, and rakkyo (Block,2010). It has been used throughout the world for both culinary and medicinal purposes (McGee, 2004) and its world production was about 25 million metric tons in 2012 (fao.org). It has a pungent and spicy flavor, which is mainly related to sulfur containing compounds such as allicin, alliin, dially disulfide, dithiin ands-allylcysteine. It is believed that dially disulfide is an important odour component in the garlic. Allicin is the component responsible for the spiciness in the raw garlic and has powerful antibiotic and antifungal properties. It derives from the precursor alliin in fresh garlic tissue through the enzymatic action of alliinase. Allicin and other degradation products from alliin also give garlic a characteristic flavor and are extracted from its essential oil(Block,1992). Essential oil is extracted from garlic with the help of modified Clevenger apparatus and radical scavenging activity of this oil is estimated using DPPH. Crude rice bran oil procured from factory is chemically refined in the lab before using it for frying purposes. Deep-fat frying involves immersion of food in hot edible oil at a temperature above the boiling point of water for a given period of time ( Farkas et al., 1996). The process involves both mass transfer, mainly represented by water loss and oil uptake, and heat transfer (Vitrac et al., 2002). Degraded lipid compounds, formed after frying such as free fatty acids, mono and diacylglycerols and polymers may affect the quality of the frying medium (Moriera,1999). In order to prevent deterioration due to oxidation use of antioxidants is practiced , which inactivates the free radical. An antioxidant , is any substance, present at low concentrations, significantly prevents or delays the oxidation of the substrates (Halliwell, 1995).Free radicals produced by oxidation reactions can start chain reactions that leads to further oxidation by chain reaction. Antioxidants terminate these chain reactions by removing free radical intermediates and inhibit other oxidation reactions by themselves being oxidized (Saha and Tamrakar, 2011). Antioxidants are of two types Synthetic and Natural. Synthetic antioxidant may cause adverse effects to humans. The International Agency for Research on Cancer classifies synthetic antioxidants such as BHA (Butylated hydroxyanisole) as a possible human carcinogen. Therefore synthetic antioxidants due to their possible deleterious effects on health need to be replaced with natural antioxidants thereby preventing the occurance of rancidity in foods and increasing their stability in a bioactive way. So in order to explore the potential of natural antioxidants from plants or edible sources for inducing and promoting rapid free radical scavenging activities in foods especially in oils, this research involving rice bran oil blended with garlic essential oil in which essential oil of garlic has been used as one such natural antioxidant and its effect on deep fat frying of Rice bran oil has been studied.

Materials and Methods

Cloves of local variety of garlic were procured from the local market at IIT Kharagpur and the transparent shell of garlic samples were removed manually and were sliced into small pieces of dirrerent sizes prior to essential oil extraction.

Extraction of Essential oil

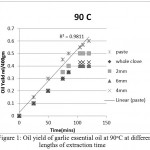

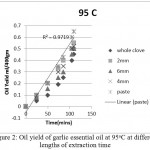

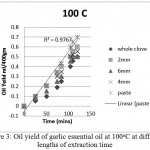

The fresh garlic (having 64+1% mc wb) was procured from the local market as and when required for the experiments and the same variety was used for all the experiments. Fresh garlic samples were subjected to separation of cloves-peeling, scaling, slicing and paste making. The moisture content of the peeled garlic cloves was determined by using gravimetric method using digital weighing balance for the quantitative determination of an moisture content based on the mass of a solid. Essential oil of garlic was extracted by hydro distillation which involves the diffusion of essential oil into hot water through the plant membrane (hydro diffusion). Modified cleavenger apparatus (Betel leaf oil extractor, Patent No. 202600) was used for extraction of essential oil of garlic (Guha 2007 and 2010). For each experiment 400 grams of garlic clove slices of desired thickness were taken into a 5 litre round bottom flask and 600 ml of water was added. Three different temperatures were taken for optimization i.e 90°C, 95°C and 100°C (Fig 3.1, Fig 3.2, Fig 3.3). The volatile oil insoluble in water was obtained after hydro distillation.

|

Figure 1: Oil yield of garlic essential oil at 90oC at different lengths of extraction time

|

|

Figure 2: Oil yield of garlic essential oil at 95°C at different lengths of extraction time

|

|

Figure 3: Oil yield of garlic essential oil at 100°C at different lengths of extraction time |

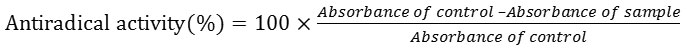

Determination of Antiradical Activity

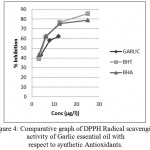

The antiradical activity of garlic essential oil was measured in terms of hydrogen-donating or radical scavenging ability by etiolation of purple colored methanolic solution of the stable radical DPPH. The diluted solutions were prepared in methanol to obtain final concentrations ranging from 4 to 12µg/mL of the stock essential oil solutions (20 µg/mL) and were introduced into test tubes. Two milliliters of fresh methanolic solution of DPPH at a concentration of 0.0015M were added. The samples were shaken and kept in the dark for four hours to develop its final colour. The decrease in absorbance at 517 nm was determined using a spectrophotometer for all samples (Fig 3.4). Methanol was used to zero the spectrophotometer and the anti radical activity was calculated by the formula given below. The radical scavenging activity of garlic was then compared to that of synthetic antioxidants such as BHT and BHA.

|

Figure 4: Comparative graph of DPPH Radical scavenging activity of Garlic essential oil with respect to synthetic Antioxidants. |

Refining of Crude Oil

Crude Rice bran oil was obtained from BK Agro oil mills Jhargram, Midnapore West Bengal. It was then refined using the process as mentioned by B.K. De and D.K. Bhattacharyya (1998). The refining processes consisted of Degumming, Dewaxing, Caustic refining. Combined degumming-dewaxing , bleaching and deodourization.

Deep Fat Frying

Refined rice bran oil was then blended with garlic essential oil with a concentration of 0.25% (which was taken as the optimum concentration after a storage study). The oil was used for deep fat frying of potato slices. The temperature of oil was maintained at 180o C using a thermocouple. The oil obtained after frying was stored and studied to measure the effect of antioxidant on Rice bran oil stability. Potato chips were fried in 20 g batches at constant frying temperature. The volume of oil was not replenished during frying operations. The used oil obtained was stored under dark before analysing for various Physico-chemical tests.

Peroxide Value Analysis

Three stages of frying were carried out with the pure rice bran oil(control) as well as with the blended rice bran oil. All the samples were stored in dark. The peroxide values of the samples were determined in terms of the method of the American Oil Chemists’ Society (AOAC, 1990). All determination were done in triplicate.

Free Fatty Acid Content

FFA percent was determined for the various oils obtained after different stages of frying. The free fatty acid was determined according the American Oil Chemists’ Society (AOAC, 1990).

Viscosity

Viscosity is related to the chemical properties of the oils such as chain length and saturation/unsaturation. The values obtained were recorded and compared using Brookfield Rheometer.

Colour Analysis

The L* a* b* values of the different samples was recorded and the observations were measured using Hunter Lab apparatus (Table 3.1).

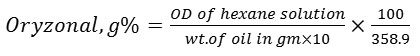

Oryzanol Content Determination

Oryzanol content was determined in accordance to the method described by Krishna et al(2006). Samples of accurately weighed RBO (10 mg each) taken in triplicate were dissolved in hexane and volume made up to 10 mL and mixed well in a vortex. Oryzanol content was determined with the formulae given below with specific extinction coefficient taken as 358.9.

FT-IR Analysis

FT-IR (Fourier transform infrared spectroscopy) was used to evaluate the degree of oxidation after heating and frying processes. FT-IR spectrum of oil samples before and after frying were recorded with the help of a Fourier Transform Spectroscopy Model I-R Prestige 21 Shimadzu and Omnix software. FTIR is used to study the saturated and unsaturated compounds of heated and unheated oils at room temperature for monitoring the oxidation process in oils.

Statistical Analysis

For statistical analysis, all the data were taken in a triplicate. Data are presented as a mean ± standard deviation (SD). The differences between independent groups were specified by two way analysis of variance (ANOVA), and values of P < 0.05 were regarded as statistically significant.

Results and Discussion

In this work an effort has been made for optimization of essential oil extraction from garlic cloves using modified hydrothermal distillation techniques which may be helpful if commercial extraction of garlic is to be done. Essential oil extraction from garlic cloves was carried out at various combinations of temperatures i.e 90, 95 and 100°C (Fig 3.1, Fig 3.2, Fig 3.3) and different set of particle sizes ( i.e whole clove, slices of 6 mm, 4 mm, 2 mm thickness and garlic paste) . The ratio of raw material and distilled water was kept constant at 1:1.5 throughout all set of combinations. Through experimental studies on hydrothermal extraction of essential oil from garlic cloves it was found that the yield of oil depended on particle size and operating temperature and maximum yield was obtained by optimizing different process parameters. The maximum oil yield was found to be 0.7ml/400grams or 1.8 ml/kg(Fig 3.3) in case of garlic paste at 100°C after 110 minutes .

Antioxidant Activity

Further in the present study, antiradical activity or antioxidant activity of the essential oil obtained from garlic was studied in Rice bran oil. Antiradical activity of essential oil of garlic as measured by the DPPH model system was found out to be 42.93%. The IC50 value of essential oil samples was found as IC50 = 6.17µg/ml. The radical scavenging activity of garlic was then compared with some of the synthetic antioxidants (Fig 3.4) and a comparative analytical graph was prepared for better understanding.

Deep Fat Frying Analysis

Deep fat frying of potato chips was carried at 180°C with pure Rice bran oil as well as the Rice bran oil blended with the garlic essential oil. Various Physicochemical parameters were assessed and the results were analysed as follows :

Peroxide Value

The peroxide value of the different samples of oils were ascertained and results were analysed.

Results show that the peroxide values for pure Rice bran oil increased from 1.73(present at normal 35°C) to 5.83meq/kg(after frying at 180°C) in case of pure Rice bran oil and to 5.13 meq/kg (third frying frying) in case of blended rice bran oil(Fig 3.5). There is a successive increase in peroxide value when the same oil was used for frying with a piece of potato. The Peroxide Values of the pure Rice bran oil and the blended Rice bran oil were found with oil samples taken out regularly after three batches of frying. The peroxide values for both the oils showed similar trends however the oil blended with antioxidant rich garlic essential oil showed lower levels of Peroxide values indicating effective role of antioxidants during deep fat frying.

|

Figure 5: Peroxide Values after various stages of frying

|

Free Fatty Acid Test

The value of free fatty acid ranged from 0.24-0.65 % for pure Rice bran oil and 0.19-0.55% for blended Rice bran oil after deep fat frying(Fig 3.6). It was observed that FFA increased significantly during deep frying in the experimental Rice bran oils as was earliar repeated by (Chaudhary2013).Blended Rice bran oil showed relatively lower levels of free fatty acids.

|

Figure 6: FFA percentage after various stages of frying

|

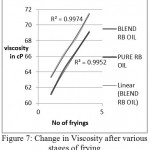

Viscosity test

The oil viscosity has a direct relationship with some chemical characteristics of the liquids, such as the degree of unsaturation and the chain length of the fatty acids that constitute the triglycerides . Viscosity slightly decreases with the increased degree of unsaturation. (Fig 3.7)

|

Figure 7: Change in Viscosity after various stages of frying.

|

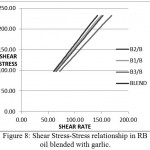

Rice bran oil is Newtonian Fluid. (Formo et al., 1979). The results demonstrate the linear dependence of shear stress on shear rate. Fig 3.8 displays Rice bran viscosity as affected by repeated frying of potato chips. As one can see there is a marked increase in Rice bran oil viscosity during repeated frying. This has been observed previously for several oil types under different experimental conditions (Miller et al., 1994).The changes in the viscosity of an oil or fat during repeated frying and heating can be expected to depend on products generated during frying and differing in molecular size like triacylglycerols (i.e. oxidation, polymerization, hydrolysis and fission products) or due to the addition of various compound like acrylamides into the oil. The increase was found to be lower in case of blended rice bran oil.

|

Figure 8: Shear Stress-Stress relationship in RB oil blended with garlic.

|

L* A* B* Color Test

Color value of the oils were measured with a Hunter Lab digital color difference meter . Values for L (lightness), a (redness), and b (yellowness) were recorded. It showed a decrease in the value of L depicting an increase in the darkness of the oils. It may be due to the addition of acrylamides to the oil (Pedreschi2009). The values of L* decreased from 72 to 65 depicting addition of components from the fried products however not much difference was found in the controlled and the blended rice bran oil (Table3.1).

Table 1: L* a* b* values of pure and blended RB oil used for deep fat frying

| Sample | L* | a* | b* |

| Pure RB oil | 72.10 + 1.35 | 3.17 + 0.35 | 8.92 + 1.25 |

| 1st Batch Frying | 67.66 + 1.89 | -1.07 + 0.55 | -2.68 + 0.75 |

| 2nd Batch Frying | 65.32 + 4.22 | -0.8 + 0.08 | -0.81 + 0.32 |

| 3rd Batch Frying | 66.23 + 3.55 | -1.81 + 0.05 | -3.91 + 0.87 |

| Blended RB Oil | 71.48 + 2.46 | 1.68 + 0.15 | 5.78 + 1.27 |

| 1st Batch Frying | 68.52 + 0.85 | 0.03 + 0.01 | 2.01 + 0.46 |

| 2nd Batch Frying | 69.32 + 2.50 | -.42 + 0.15 | -1.29 + 0.15 |

| 3rd Batch Frying | 66.95 + 3.57 | -1.75 + 0.26 | -2.92 + 0.39 |

Oryzanol Content Determination

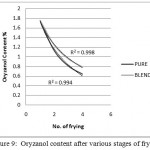

The natural antioxidant present in the rice bran oil was determined using UV spectrophotometer method. The oryzanol content decreased with the frying cycles. Figure showed the degradation of γ-oryzanol in pure RBO over the frying cycles. The concentration of γ-oryzanol in RBO was seen to decrease significantly however the oil containing garlic essential oil showed a higher oryzanol retention indicating a synergistic effect of the two natural antioxidants. In accordance to the number of frying batches. Fresh oil, containing 1.75 %-oryzanol, was reduced to 0.64% at the third cycle while as for the blended oil it was to 0.8% (Fig 3.9).

|

Figure 9: Oryzanol content after various stages of frying

|

Ftir Analysis

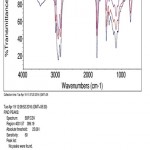

Fig 3.10 and Fig 3.11 show the FTIR spectra of pure and blended rice bran oil. Almost all the transmissions were found to be the same. The decrease in transmission from 3465cm -1 (fig 3.10) to 3432cm-1 reveals the lack of formation of hydroperoxide . This might be due to the effectiveness of antioxidants in RBO. Transmission at 3008 cm -1 shows the higher presence of Linoleic and linolenic acyl groups. 2854 cm-1 has been formed due to symmetric and asymmetric stretching of –CH 2 group . The broadening of 1743 to 1744 cm -1 may be due to production of saturated aldehydes functional groups.

|

Figure 10: FTIR graph of pure RB Oil at all three stages of frying

|

The transmission rate in case of the pure Rice bran oil was observed to be higher(Fig 3.10) than that of Blended Rice bran oil(Fig3.12) depicting higher deterioration in case of pure rice bran oil. The comparatively lower transmission rates in blended Rice bran oil may be due to the presence of antioxidants in it. There is a slight difference in intensity in peaks at 3007cm-1 and 1237cm-1 depicting that the thermal degradation in the pure sample is slightly more than the blended sample

The following graph(Fig 3.11) was found out after third level of frying for the two samples consisting of blended Rice bran oil and the pure rice bran oil. Pure garlic oil (Fig 3.10) showed higher transmission rates compare to the blended one.

|

Figure 11: FTIR graph after first stage of frying for pure and blend RB Oil.

|

|

Figure 12: FTIR graph of blended RB oil after third stages of frying.

|

Summary and Conclusions

Essential oil from garlic was extracted through modified Clevenger assisted hydrodistillation setup. Maximum oil yield was obtained in the paste form (1.8ml/kg) due to maximum exposed surface area to the heat. Temperature optimization was carried out for modified Clevenger assisted hydrodistillation setup and it was found out that maximum oil yield can be obtained at 100oC for 110 minutes of running the setup. The radical scavenging activity of essential oil of garlic was determined using DPPH assay and IC50 values were found out using regression model in excel. The IC50(Inhibition Capacity) value which is the concentration of the sample required to decrease the absorbance of DPPH by 50% (IC50) obtained was 6.17µg/ml which depicted a moderate antioxidant activity in the essential oil. The values obtained were compared to that of some of the commonly used synthetic antioxidants such as BHA and BHT. The synthetic antioxidants showed a higher antioxidant activity than the garlic essential oil.

Rice bran oil was chemically refined in the lab and was blended with various concentrations of garlic essential oil. The optimum concentration of garlic essential oil was chosen to be 0.25% (after storage study analysis) and was blended with Rice bran oil. Deep fat frying of Rice bran oil at 180oC was done and three stages of frying were carried out to assess the various physicochemical features of oil. The peroxide value of blended Rice bran oil showed a slightly lower value than the pure sample containing only Rice bran oil however after second stage of frying the effect of antioxidant ceased to exist due to heating at very high temperature. The maximum peroxide value of rice bran oil was found at 5.13 meq/kg for blended oil while as it was 5.80 meq/kg for the pure rice bran oil after three levels of frying(Fig 3.5). Values for L (lightness), a (redness), and b (yellowness) were recorded which showed a decrease in the value of L depicting an increase in the darkness of the oils(Table3.1). It may be due to the formation of acrylamides to the oil. Viscosity of oil was found out for oil samples taken after three stages of frying. The results showed an increasing trend in viscosity after every level of frying, it may be due to the addition of amides from the fried product into the oil. Based on the rheograms, all the samples of Rice bran oils studied were found to be Newtonian fluids. Oryzanol content was determined for all the samples of Rice bran oils and there was a constant decrease in the oryzanol content after each level of frying(Fig 3.9). However rice bran oils added with garlic essential oil showed a slightly higher oryzanol retention hinting of scope for a study of synergistic effect of garlic essential oil with oryzanol. FTIR analysis of rice bran oil of unheated and heated rice bran oil was performed which showed that almost all the trends of the transmissions are found to be the same. The decrease in transmission from 3465cm-1 to 3432cm-1 revealed the lack of formation of hydroperoxides(Fig 3.10, 3.11, Fig3.12). This might be due to the presence of of antioxidants in RBO. However higher transmissions were obtained for the pure Rice bran oil depicting a comparative higher level of of degradation. Rice bran oil is a stable oil good for frying and addition of garlic essential oil proves to be beneficial in adding more stability to the oil.

Acknowledgement

The authors would like to express their sincere appreciation to Department of Agricultural and Food Engineering, Indian Institute of Technology Kharagpur for supporting this project financially.

References

- Abiona O. O., Awojide S. H., Anifowoshe A. J and Babalola O. B. Comparative study on effect of frying process on the fatty acid profile of vegetable oil and palm oil. E-International Scientific Research Journal. 2011;3(3):210-219.

- Block E. Garlic and Other Alliums: The Lore and the Science. Royal Society of Chem‐istry. ISBN 0-85404-190-7. 2010.

- Block E. The organosulfur chemistry of the genus Allium–implications for the organic chemistry of sulfur. Angewandte Chemie International Edition in English. 1992;31(9):1135-1178.

CrossRef - Choe E and Min D. B. Chemistry of deep‐fat frying oils. Journal of food science. 2007;72(5):R77-R86.

CrossRef - Choudhary M and Grover K. Effect of deep-fat frying on physicochemical properties of rice bran oil blends. IOSR J. Nurs. Health Sci.(IOSR-JNHS). 2013;1:1-10.

CrossRef - Choudhary M and Grover K. Effect of deep-fat frying on physicochemical properties of rice bran oil blends. IOSR J. Nurs. Health Sci.(IOSR-JNHS). 2013;1:1-10.

CrossRef - De B. K & Bhattacharyya D. K. Physical refining of rice bran oil in relation to degumming and dewaxing. Journal of the American Oil Chemists’ Society. 1998;75(11):1683-1686.

CrossRef - Dupuy N., Duponchel L., Huvenne J. P., Sombret B and Legrand P. Classification of edible fats and oils by principal component analysis of Fourier transform infrared spectra. Food Chemistry. 1996;57(2):245-251.

fao.org/site/339/default.aspx.

CrossRef - Farkas B. E., Singh R. P and Rumsey T. R. Modeling heat and mass transfer in immersion frying. I model development. Journal of food Engineering. 1996;29(2):211-226.

CrossRef - Formo M. W. Physical properties of fats and fatty acids.Bailey’s industrial oil and fat products. 1979;1:177-232.

- Granda C., Moreira R. G and Tichy S. E. Reduction of acrylamide formation in potato chips by low-temperature vacuum frying. Journal of Food Science. 2004;69(8):405-411.

- Gulçin İ., Sat I. G., Beydemir S and Küfrevioglu O. I. Evaluation of the in vitro antioxidant properties of broccoli extracts (brassica oleracea l.). Italian journal of food science. 2004;16(1).

CrossRef - Halliwell B.How to characterize an antioxidant: an update. In Biochemical Society Symposia. Portland Press Limited. 1995;61:73-101.

CrossRef - IARC Monographs on the Evaluation of Carcinogenic Risks to Humans Schistosomes Liver Flukes and Helicobacter Pylori. International Agency for Research on Cancer. 1994.

- Kaur H and Perkins J. The free radical chemistry of food additives. In, Aruoma OI Halliwell B (Ed) Free radicals and food additives. 1991;17–35.

- Kim I and Choe E. Oxidative stability and antioxidant content changes in roasted and bleached sesame oil during heating. Food Science and Biotechnology. 2004;13(6):762-767.

- Kita A and Lisinska G. The influence of oil type and frying temperatures on the texture and oil content of French fries. Journal of the Science of Food and Agriculture. 2005;85(15):2600-2604.

CrossRef - Krishna A. G., Hemakumar K. H & Khatoon S. Acidity of oryzanol and its contribution to free fatty acids value in vegetable oils. Journal of the American Oil Chemists’ Society. 2006;83(12):999-1005.

CrossRef - Lu Y & Foo L. Y. Antioxidant activities of polyphenols from sage (Salvia officinalis).Food chemistry. 2001;75(2):197-202.

CrossRef - Miller K. S., Singh R. P & Farkas B. E. Viscosity and heat transfer coefficients for canola, corn palm and soybean oil. Journal of Food Processing and preservation. 1994;18(6):461-472.

CrossRef - Moreira R. G., Castell-Perez M. E & Barrufet M. Deep fat frying: Fundamentals and applications. Boom Koninklijke Uitgevers. 1999.

- Pambou N., Kama R. T and Linder M. RSM applied for optimization of deep-fat fried ripe plantain slices and study of oxidation kinetics of oil by a DSC and polar methods. J Food Sci Technol. 2016;53(1):2–2.

- Patel M and Naik S. N. Gamma-oryzanol from rice bran oil a review. Sci. Ind. Res. 2004;63:569-578.

- Saha D and Tamrakar A. Xenobiotics Oxidative Stress Free Radicals Vs. Antioxidants Dance Of Death to Heaven’s Life. Asian Journal of Research in Pharmaceutical Science. 2011;1(2):36-38.

- Serjouie A., Tan C. P., Mirhosseini H and Che Y. M. Effect of frying process on fatty acid composition and iodine value of selected vegetable oils. 2010.

- Van V. H., Depaemelaere G., Ayala J. V., Santiwattana P., Verhe R and Greyt W. D. Influence of chemical refining on the major and minor components of rice brain oil. Journal of the American Oil Chemists’ Society. 2006;83(4):P315-321.

CrossRef - Vitrac O., Dufour D., Trystram G and Raoult-Wack A. L. Characterization of heat and mass transfer during deep-fat frying and its effect on cassava chip quality. Journal of Food Engineering. 2002;53(2):161-176.

CrossRef - Zahir E., Saeed R., Hameed M. A and Yousuf A. Study of physicochemical properties of edible oil and evaluation of frying oil quality by Fourier Transform-Infrared (FT-IR) Spectroscopy. Arabian Journal of Chemistry. 2014.

This work is licensed under a Creative Commons Attribution 4.0 International License.