Manuscript accepted on :

Published online on: 24-12-2015

Vadim Igorevich Bespalov, Oksana Sergeevna Gurova, Oksana Nickolaevna Paramonova* and Ekaterina Petrovna Lysova

Federal State Budgetary Educational Institution of Higher Professional Education, “Rostov State University of Civil Engineering” , Russian Federation 344022, Rostov region, Rostov-on-Don, Socialisticheskaya St., 162

ABSTRACT: In the given article the authors offer an evidence-based technique for the solution of the problem of assessment and choice of the most ecologically effective and energetically economic technologies of air purification of toxic components of the departing and exhaust gases of objects in the conditions of urban environment. The technique development included consideration of a hydrodynamic method of flue gases purification of the toxic polluting substances on the basis of studying the physical features in course of the process, mathematical description of the method by criteria of ecological efficiency and energy efficiency parameter. At the final stage of the conducted research the technique of the assessment and choice of the most ecologically effective and energetically economic technologies of toxic components of the departing and exhaust gases of objects cleaning in the conditions of urban environment provided with algorithm for its realization has been developed.

KEYWORDS: criteria of an optimum technology choice of purification of flue gases realization process; hydrodynamic method of purification of flue gases; ecological efficiency; energy efficiency parameter; technique of the most ecologically effective and energetically economic means of purification of flue gases of toxic components choice

Download this article as:| Copy the following to cite this article: Bespalov V. I, Gurova O. S, Paramonova O. N, Lysova E. P. Development and Choice of an Evidence-Based Technique of the Most Ecologically Effective and Energetically Economic Technologies of Cleaning of Toxic Components of the Departing and Exhaust Gases of Objects of an Urban Environment Assessment. Biosci Biotech Res Asia 2015;12(2) |

Introduction

In modern conditions the existing planning of urban areas includes as a rule industrial and recreational zones which are located not only considering natural, but also economic and social conditions. Usually industrial zones settle down on suburbs or outside the city, however, the enterprises of building industry, construction objects, the enterprises of the housing-and-municipal sphere (heat and power engineering enterprises and transport) remain within urban area and, thereby, are the main sources of atmospheric air pollution (Grigoriev, Ogorodnikov, 2001; Mcdonald, 2012).

Ratio between emissions (Read, et al., 1982) of the listed sources in the world practice goes approximately as follows: power emissions ( Katzenstein and Apt, 2009; Zhao, et al., 2008) about 60%, transport (Hickman, et al., 1999; Soylu, 2007) 20-25%, industrial 15 – 20%. In different countries this ratio can vary depending on local conditions: industrial development and its role in separate branches, motor transport saturation (Costabile, Allegrini, 2008), climate conditions, requirements to environment protection and equipment, cleaning of emissions condition (Ilchenko, 2009).

The reasons of considerable emissions into atmosphere are: absence or inefficient localization of gases and dust release sources; insufficient air tightness, constructive shortcomings of the production equipment, its technical malfunction; incorrect technological processes conducting, etc (Khotko, Dmitriev, 2012; Qingsong Wang, et al., 2013).

Expansion of many types goods production involves increase of air basin pollution level (Bhanarkar, et al., 2005). Development and improvement of production, introduction of new types of goods and technological processes have to be followed by development and implementation of events for atmospheric air pollution prevention.

Only by means of systems and devices for air purification improvement, as a rule, it is impossible to achieve any substantional decrease in the air environment pollution level. All the events for air pollution decrease have to be performed in complex.

Alongside with the use of effective dust removal devices and systems dealing with features of polluting substances and multistage cleaning, different kinds of technological measures have to be developed and carried out: equipment pressurization, application of the built-in closed local suctions, replacement of dry processes with wet processes, remote control, processes automation excluding direct contact of workers with polluting substances.

Thus, it is possible to conclude that the solution of the atmospheric air pollution problem can be possibly in realization of various arrangements as well as methods, ways and technical design types. This consequently causes a problem of the final decision choice allowing to reach the maximum ecological efficiency and energy profitability for the technologies of air purification of toxic components of exhaust gases for urban environment objects.

The majority of now existing calculations, design types and operational parameters of engineering complexes of decrease of the air environment pollution assessment procedures are based on use of a resultant criterion of process efficiency realization in general or on its separate stages. The concept of effectiveness is frequently identified with the concept of efficiency that contradicts classical definition of efficiency as energy process assessment. This type of connection does not allow to characterize the system behavior and to offer any management over this process. Such management necessity arises every time at an optimum change of stability of disperse systems choice in course of air environment pollution decrease. Moreover, development of modern means of air environment pollution decrease gives an opportunity to offer some various engineering decisions for achievement the same demanded efficiency value. That means, efficiency is not sufficiet as optimizing criterion today. Therefore now the optimization process is multicriterial and assumes the use of not only the main criterion (efficiency) but also of a number of additional criteria: for the process of energy profitability assessment – energy efficiency parameter; for the engineering system steady work assessment – technological reliability parameter; for the material and financial means expenses assessment – economic efficiency parameter. In our opinion, the two criteria should be considered as the main: ecological efficiency and an energy efficiency parameter which are used by us when developing a technique of the assessment and choice of the most ecologically effective and energetically economic technologies of cleaning of toxic components of the exhaust gases based on a hydrodynamic method use.

Thus the purpose of our research was the development of an evidence-based technique for the assessment and choice of the most ecologically effective and energetically economic technologies of cleaning of toxic components of exhaust gases for urban environment objects. The research essence is in consideration of the toxic polluting substances as a disperse system with certain properties consisting of a disperse phase (firm, liquid, gaseous) and the gaseous dispersive environment (air). Consideration of disperse system properties allows to define the main types of its impact for the purpose of the city air environment pollution decrease. For this purpose achievement the following tasks have been solved by us:

- toxic substances as disperse systems have been considered;

- the hydrodynamic method of flue gases purification of the toxic polluting substances on the basis of physical features studying in the course of process has been considered;

- the mathematical description of the method of ecological efficiency and energy profitability as resultant criteria of the technology emissions cleaning choice has been executed;

- the technique of assessment and choosing the most ecologically effective and energetically economic technologies of exhaust gases emissions cleaning of urban environment objects has been developed;

- the algorithm of practical realization of a technique of the assessment and choosing the most ecologically effective and energetically economic technologies of exhaust gases emissions cleaning of urban environment objects has been developed.

Methodology

Methods of our research are based on probability theory basic statements as well as mathematical statistics, the theory of disperse systems, the system analysis, analytical generalization of known scientific and practical results and other methods.

Results and Discussion

The research conducted by the authors shows that the process of purification of flue gases at the industrial and power enterprises, municipal and household power stations as well as exhaust gases of transport devices and mobile power stations from the toxic polluting substances according to the offered physic energy concept (Bespalov, 1995; Bespalov, 1997) can be organized by various methods which are characterized by the corresponding physical essence of the organized external influence (aerodynamic, hydrodynamic, mechanical, optical, electromagnetic, etc.) . Further each method of cleaning can be implemented in various ways characterizing physical form of the external influence organization. Each way can be performed by the corresponding different types of realization which characterize technological parameters of the organization of external influence, and each type of realization is performed by various technical means representing definite devices where any combination “method-way-look-technical means” exists.

The problem of the demanded ecological efficiency and maximum energy profitability of flue gases of toxic polluting substances purification technology process choice may be determined by a method, a way, a look and a definite technical solution at their great variety is very actual for real production and technological conditions. This task relevance is emphasized also with the fact that the same value of ecological efficiency can be achieved practically by their any combination.

In our opinion the choice of optimum technology of flue gases purification for any urban environment definite object process realization has to be based on the use as optimizing criteria ecological efficiency and energy efficiency parameter described in work (Bespalov et al., 2014) under the condition that their mathematical description for obtaining corresponding dependences on the parameters characterizing the toxic polluting substances properties, surrounding air environment properties, toxic components emission features, as well as properties of the factors influencing those toxic components in the course of cleaning will be given.

As an example the mathematical description of the hydrodynamic method of flue gases of the toxic polluting substances purification executed by the authors in conditions of low pressure and high-pressure irrigation on the basis of the considered process physical features is presented in article. Considering that technological features in the conditions of low pressure irrigation are connected with receiving drops of the dispersed liquid of 300-1000 microns in size under the pressure 0,2-2,0 MPa and in the conditions of high-pressure irrigation – 10-100 microns in size under the pressure of 7,0-20,0 MPa, the analysis of the main physical mechanisms of these processes realization with the aim to assess efficiency from the point of view of the mass transfer theory has been carried out by the auhtors (Gurova, 2000).

The fact that gas solution in liquid coexists with the over liquid gas is known (Read, et al., 1982). Thus the content of gas in the solution depends not only on gas and liquid sort but also on pressure, temperature and gas phase structure. In equilibrium state between both phases gas concentration some ratio characterized by constant phase balance (m) equal to the concentration relation in gas phase Cg to its concentration in liquid phase Cl is established:

In case of phases balance absence the process of mass transfer of substances from one phase into another is carried out. The mass transfer is a complex process consisting of substance transfer within each of phases (mass output) and substance transfer over the phase separation limit.

The motive force of substance transfer process is the deviation of system from balance, i.e. concentration gradient. According to the Fick’s law the quantity of W gas components transferred in the direction z through F surface for a unit of time makes:

or

where Δ – the motive force; K – the mass transfer coefficient representing the amount of substance transferred from one phase to another in a unit of time over the surface with the motive force equal to the unit, determined by the equation:

where βg, βl – mass output coefficients respectively in gas and liquid phase.

The conducted researches of both Russian and foreign authors (Rodionov, et. al. 1965) showed that the coefficients determination of mass output and mass transfer is the most difficult stage at calculation of air purification process with liquid systems and demands preliminary experimental studies. Known dependences of cleaning efficiency determination do not reflect features of gaseous and liquid phases interaction depending on their physical and chemical properties, technological and working conditions.

At the same time it is established that air streams cleaning with liquid systems is a difficult multistage and multiple-factor process of system components interaction «a polluting substance particle (PS) – liquid» between themselves as well as within environment and is characterized by the group of dependent and independent parameters (Gurova, 2000).

On the basis of consideration of interaction process between the two disperse systems of disperse phases as a set of separate processes of PS particle interaction with a drop of liquid it is possible to assume that the effective air purification with a hydrodynamic method of irrigation with a liquid aerosol requires fulfillment of the four consecutive stages which are carried out with a certain degree of probability.

The first stage of cleaning process via irrigation occurs at rapprochement of a PS particle with a drop to distances on which molecular forces of these particles and liquid interaction start acting. Thus it is necessary to consider simultaneous action of turbulent and diffusive forces. The second stage includes transition of a PS particle to the area of the phases section border. At this stage molecular, electrostatic and diffusive forces have the main impact. Penetration of a PS particle into liquid characterizes the third stage of process where it is necessary to consider diffusive forces and a course of chemical reaction between a PS particle and liquid. The fourth stage defines sedimentation of drops with the taken PS particles from air stream by gravitation forces.

The probabilistic approach considering consecutive realization of four allocated process stages that is mathematically expressed by product of probabilities with use of probability theory and mathematical statistics is applied to the solution of the efficiency determination of air purification with the hydroirrigation task. Thus we will understand efficiency of this or that process stage as probability of its implementation.

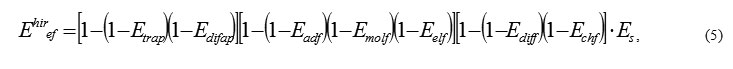

In this case the general formula of efficiency process of gas purification with hydroirrigation has the look:

where Etrap, Edifap – efficiency of rapprochement of a PS particle with a drop respectively at the expense of turbulent and diffusive forces; Еadf, Emolf, Eelf – efficiency of a PS particle transition to area on limit of the phases section border at the expense of respectively adsorptive, molecular and electrostatic forces; Ediff, Echf – efficiency of a PS particle penetration into liquid at the expense of respectively diffusive and chemical forces; Еs – efficiency of drops subsidence with the taken PS particles from air stream by gravitation forces.

We will consider process of cleaning efficiency at every stage of process.

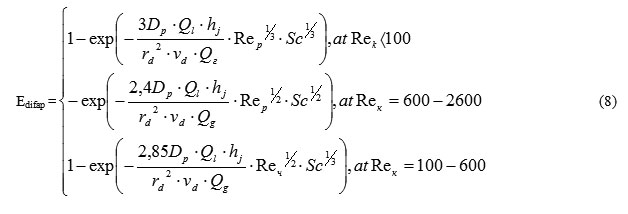

Efficiency of a PS particle rapprochement with a drop due to diffusion is defined as a relation of number of PS particles, which approached the drop to the total number of these particles in the active zone of interaction.

Having made transformation we receive:

where Dp – the average median diameter of PS particles, m; Ql – consumption of the irrigating liquid, m3/s; Qg – consumption of the air coming with PS particles to the active cleaning zone, m3/s; vd – the average speed of a drop in the active cleaning zone, m/s; rd – the average median radius of a drop, m.

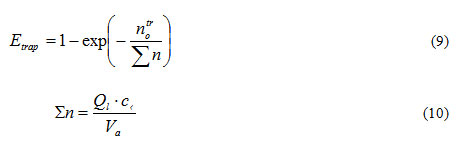

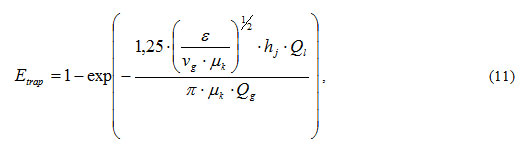

Efficiency of rapprochement of PS particles with drops at the expense of turbulent forces is defined as the relation of PS particles quantity, which approached the drops and a total number of PS particles in the active cleaning zone:

where

Then, having substituted (10) with (9), we receive:

where hj – length of the active zone irrigation jet, m; vg – air (gas) stream speed, m/s; μk – kinematic viscosity of air (gas), m2/s.

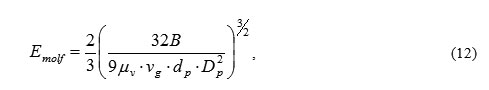

Efficiency of transition of a PS particle to the area of the phases section border at the expense of molecular forces:

where B ~ 10-26 – a constant of intermolecular interaction taking into account electromagnetic delay effect, J/m2; μv – dynamic air viscosity, Pa; dp – the mean superficial and three dimensional drop diameter, m.

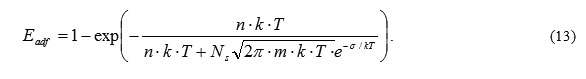

Efficiency of gas molecules transition due to adsorption is counted with a formula:

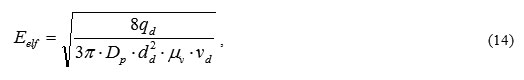

Efficiency of gas molecule transition to the area of the phases section border at the expense of electrostatic forces:

where qd – a drop charge, C. It is possible to determine efficiency of a PS particle penetration into liquid volume due to chemical interaction with the following dependence:

![]()

where Kr – a constant of speed of chemical interaction reaction between PS particles and water, C-1; τ – time of a PS particle stay in volume of water, s.

Efficiency of subsidence of the formed units (PS particles with liquid drops) from the air stream by gravitation forces:

where Dus – the average median diameter of sediment units, m; Da – the average median diameter of the units formed in the active cleaning zone, m; mi – the maintenance of i– size drops.

The minimum diameter of the units managed to sediment at a length area from a nozzle to the active cleaning zone border is determined by the formula:

where l – distance from a nozzle, m; ρl – irrigating liquid density, kg/m3; hj – length of the active zone irrigation jet, m.

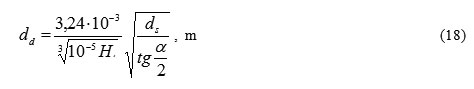

The mean superficial and three dimensional drop diameter is determined by the formula:

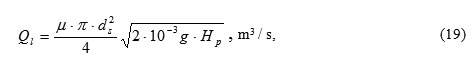

The irrigating liquid consumption can be calculated with the equation of the stream continuity:

where μ – coefficient of the sprinkler nozzle expense depending on the spray type and considering liquid expiration features (μ = 0,02-1,00); ds – sprinkler nozzle diameter, m; Hs – pressure of the irrigating liquid at the sprinkler, produced by pump, Pa.

The value Sc represents the dimensionless value characterizing relative speeds of diffusive and convective transfer at a constant Rec. It is defined as:

The active zone irrigation jet volume can be calculated taking into consideration its geometrical parameters:

The drop mass is determined by its mean superficial and three dimensional drop diameter:

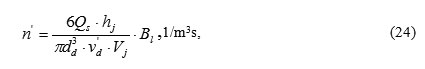

Total quantity of drops in a volume unit taking into account the temporary amendment of the drop speed is calculated with the formula:

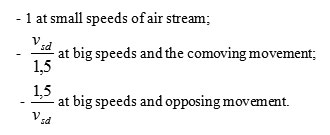

where Bl – the coefficient considering the direction and size of air stream speed and equal to:

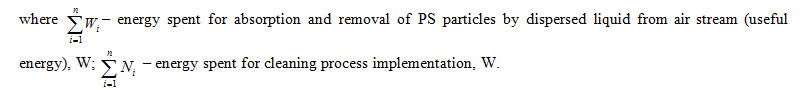

The energy efficiency parameter for the cleaning process with irrigation in a general view is defined by the formula:

The energy efficiency parameter allows us to estimate how effectively the spent energy used from the point of view of the purpose of process achievement of the air stream cleaning of PS. The detailed analysis of the operating mechanisms in the frames of PS particles and liquid phases interaction process allows to effectively use each of these mechanisms, to define ways of cleaning process with irrigation improvement and to have an opportunity of analytical forecasting on the basis of its working parameters. The energy efficiency parameter of cleaning process allows us to estimate a complex work of several techniques applied in one (step) system of cleaning.

Rapprochement of PS particles with drops of the dispersed liquid in the air stream can lead to their capture. Thus diffusive and turbulent forces have main impact on rapprochement of PS particles with a drop.

We will consider the energy parameters directly influencing the capture and removal of PS particles from the air stream with dispersed liquid. The first stage of cleaning process to start, it is necessary to transfer kinetic energy providing sediment possibility of its rapprochement with PS particles to a liquid drop. Therefore, kinetic energy of liquid drops in which interface diffuses PS particles plays a positive role from the point of view of the mechanism of air purification in the process of irrigation. The parameter considering this type of energy is described by the equation:

![]()

where md – the drop mass, kg; vd – the drop speed, m/s; n ‘- number of the drops which faced PS particles in unit of volume in unit of time, 1/m3s; Va – the volume of the active zone of irrigation, m3.

The first stage of coagulation process is characterized by the prevailing influence of adhesive forces (including aerodynamic and molecular streamline) from the point of view of PS particles capture. It is possible to estimate these forces impact with the energy of adhesive interaction, which causes attraction, and consequently plays a positive role in cleaning process. The parameter considering adhesive interaction energy is described by the equation:

where Wd – dispersive interaction energy, J; hA – average distance between a PS particle and a drop in the active zone of an irrigation, m; FA – the total surface area of adhesive interaction of liquid drops with PS particles in a unit of volume, m2/m3; τ – time during which a drop and a PS particle are in dynamic contact, c.

The necessary condition of the process of heterocoagulation of a PS particle with a liquid drop completion is strong contact between them and a contact angle of wetting formation. Spreading the liquid on a PS particle surface can be described quantitatively with the energy parameter of spreading:

where Fs – the total surface area of spreading in a unit of volume, m2/m3; τ/ – time of wetting, s.

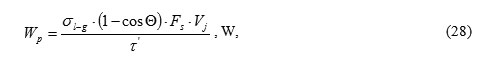

To realize a definite way of hydrodynamic air purification with low pressure or high-pressure irrigation in certain working conditions, the technical means allowing to reach the corresponding technological parameters of irrigation (ventilating streams draft activator, pump and others) are necessary. Thus the specified technical means demand certain energy expenses:

– energy parameter of ventilating streams draft activator characterizes energy of the air stream in the section of the forcing sucker of the draft activator and is described by the equation,

which taking into account the equation of air stream continuity and transportation element design characteristics (air tubes or gas flues) is led to the look:

where Hfs – pressure in the section of the forcing sucker of the draft activator, Pa; dfs – the equivalent diameter of the forcing sucker of the draft activator, m;

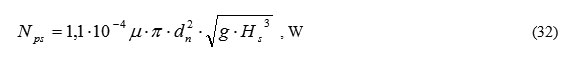

– energy parameter of pump installation characterizes energy of liquid stream at the sprinkler and is described by the equation,

which taking into account the equation of liquid stream continuity and sprinkler design characteristics is led to the look:

where μ – sprinkler nozzle expense coefficient; dn – diameter of the sprinkler nozzle, m; Hs – liquid pressure at the sprinkler, Pa.

– energy elektrolyzer parameter in case of use various classes liquid systems for gas-polluted air irrigation characterizes irrigating liquid energy condition and is described by the equation:

![]()

where Ue – current electric tension in elektrolyzer, W; Ie – current strength in elektrolyzer, A.

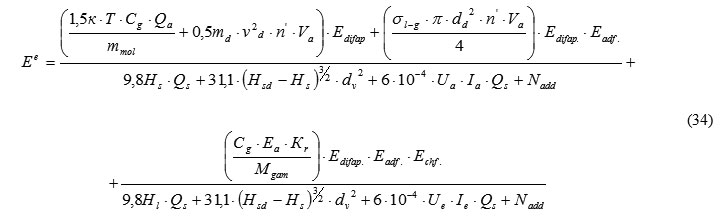

Having substituted (26)-(33) to (25), we receive:

where Hl – pressure loss on transportation element length (air tubes or gas flues) from the draft activator to the irrigation active zone, Pa; Nadd – energy parameter considering additional preparation of the irrigating liquid (chemical compounds additive, etc.) and additional processing of air (gas) stream (ozonization, etc.), W.

The formula (34) surely doesn’t consider all possible physical mechanisms at interaction of PS particles and irrigating liquid drops. However the structure of this formula, in our opinion, allows to supplement and specify the energy efficiency parameter of Ee in course of new mechanisms identification and receiving the quantitative estimates characterizing them, to receive more and more exact estimates.

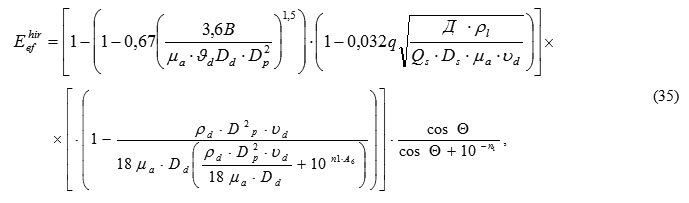

Parametrical dependence of efficiency:

where B – a constant of intermolecular interaction, J · m2; q – liquid aerosol electro charge, C/kg; n1 – coefficient characterizing the high-speed mode of liquid aerosol distribution in the active cleaning zone; Ad – coefficient of overlapping completeness of the cross section of the active cleaning zone with the dispersed liquid jet.

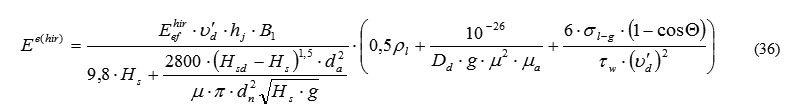

Parametrical dependence of the energy efficiency parameter:

where B1 – coefficient considering the direction and size of PS stream speed in the active zone cleaning process; Нs – the liquid pressure produced by the pump at the sprinkler, Pa; Нsd – total air pressure in the soaking-up (forcing) section of the draft activator (fan), Pa; Нl – pressure losses in transportation element network (air tubes or gas flues) from the soaking-up (forcing) section of the draft activator (fan) to the initial border of the cleaning process active zone, Pa; da – the equivalent diameter of cross section of the cleaning process active zone, m; τw – time of a PS particle wetting with a dispersed liquid drop, s; dn – diameter of sprinkler nozzle opening, m; μ – coefficient of sprinkler nozzle opening expense; hj – length of the irrigation jet active zone, m.

The presented example of the mathematical description has been determined by us as the basis for development of the choice technique of the most ecologically effective and energetically economic means of flue gases purification of toxic components which includes the following main stages:

The first stage provides collection of information about really possible technological parameters of the realization process of flue gases purification of toxic components in operating conditions of a definite urban environment object with a definite source of their emission into atmosphere (possibility of liquid, porous material, vortex air stream, foam, steam, electromagnetic field, thermal stream, use).

At the second stage it is necessary to execute technologies options sorting (method-way-look) of flue gases purification of toxic components realization process on the basis of the collected at the first stage information as well as the set operating conditions of a definite urban environment object.

The third stage provides comparison of technological features and parameters defined at the second stage technologies options (method-way-look) realization process of flue gases purification of toxic components with the considered object of urban environment characteristics and the features of the object location (air overwetting inadmissibility, its temperature and mobility excess, explosion and fire safety, electrical safety, etc.). Selection of technological options was provided in accordance with technological features and parameters with the listed demanded conditions.

The fourth stage provides additional selection within all the determined at the third stage technologies options (method-way-look) of flue gases purification of toxic components realization process and cleaning efficiency calculation (Eef) for the corresponding parametrical dependences only of those options which provide achievement of the maximum concentration limit (MCL) of the surface air in the city building territory. Thus:

- in case the condition of MCL is provided only for one option, the fourth stage finishes with this cleaning technology choice, its technological parameters calculation, design and realization with the appropriate technical means selection;

- in case the condition of maximum concentration limit is not provided for any option, the fourth stage finishes with maximum efficiency possessing cleaning technology choice, its technological improvement with the aim of increasing efficiency to the demanded level, calculation of its technological parameters, design and realization with the appropriate technical means selection;

- in case the condition of maximum concentration limit is provided for several options, the fourth stage finishes with the calculation of energy Ken criterion for all these options and additional selection of cleaning technologies is carried out. Thus:

- in case the maximum value of Ken has only one option of cleaning technology, its technological parameters calculation, design and realization of the appropriate technical means selection is carried out;

- in case the maximum (identical) value of Ken have a few options of cleaning technology, those options are accepted for further consideration.

The fifth stage provides calculation for the corresponding parametrical dependence of an energy efficiency parameter of Ee for every selected at the fourth stage (in case they are more than one) option technology of flue gases purification from toxic components realization process as the final choice of optimum cleaning technology. Thus:

- in case the maximum Ee value possesses only one option of cleaning technology, the optimum calculation of technological parameters, design and realization with the selection of appropriate technical means are carried out for it;

in case the maximum (identical) Ee value possess a few options of cleaning technology, the choice of an optimum option is carried out on the minimum of the spent energy N corresponding values then the calculation of technological parameters, design and realization with selection of the appropriate technical means are carried out (Mishner and Bespalov, 2003; Strakhova et al.,2002).

The considered technique is provided with algorithm which flowchart is submitted in figure 1.

Thus, this technique, in our opinion, can be the basis for further researches as it fully considers the set of various properties such as polluting substances and components of the surrounding urban environment.

The main advantage of the offered technique, unlike all others is the choice of ways and means of air environment pollution decrease in the cities can be made at an object design stage.

The results of the researches conducted by us can be approved in practice for the choice of the most ecologically effective and energetically economic technology of departing and exhaust gases purification of the building industry objects and life support systems of the city.

Conslusion

As a result of the conducted researches we achieved the main aim – the evidence-based technique of a choice of the most ecologically effective and energetically economic means of flue gases purification of toxic components is developed.

For this aim achievement the following tasks have been solved:

- the detailed analysis of the operating mechanisms in the course of PS particles and liquid phase interaction at the hydrodynamic method of flue gases purification of toxic components realization has been carried out;

- the mathematical description of the hydrodynamic method of flue gases purification of the toxic polluting substances by low pressure and high-pressure irrigation has been submitted;

- the technique of a choice of the most ecologically effective and energetically economic means of flue gases purification of toxic components presented in the algorithm form for its realization has been developed.

|

Figure 1: Algorithm of realization of a technique |

It will allow to execute an assessment and choose the most ecologically effective and energetically economic technologies (method-way-look) of flue gases purification at the industrial and power enterprises, municipal and household power stations, as well as transport devices exhaust gases and mobile power stations from the toxic polluting substances eventually decreasing atmospheric air pollution.

Acknowledgments

The authors express their sincere gratitude to the staff of the Department of Environmental Engineering, Federal State Budgetary Educational Institution of Higher Professional Education “Rostov State University of Civil Engineering” for advice and recommendations kindly given while writing of this article.

References

- Bespalov, V. I. (1995). The physic energetic concept of the description of processes and system approach to a choice of highly effective and economic engineering complexes of air environment protection against the polluting substances emissions // the Magazine “SKNTS High School News. Natural sciences” Rostov on Don, 1995. – P. 37-47.

- Bespalov, V. I. (1997). The physic energetic concept of the processes description and engineering complexes design considering air environment protection. Interhigher education institution. Scientific publications “Safety, Labor and environmental protection”, Rostov on Don, publishing house of RGASM, 1997.

- Bespalov, V. I., Gurova, O. S., Samarskaya, N. S., Lysova, E. P., Mishchenko, A. N. (2014). Development of Physical and Energy Concept for Assessment and Selection of Technologies for Treatment of Emissions from Urban Environment Objects. BIOSCIENCES BIOTECHNOLOGY RESEARCH ASIA, December 2014. Vol. 11(3), 1615-1620.

- Bhanarkar, A.D., Rao, P.S., Gajghate, D.G., Nema, P. (2005). Inventory of SO2, PM and toxic metals emissions from industrial sources in Greater Mumbai, India. Atmospheric Environment, July 2005, Volume 39, Issue 21, p. 3851–3864.

- Costabile, F., Allegrini, I. (2008). A new approach to link transport emissions and air quality: An intelligent transport system based on the control of traffic air pollution. Environmental Modelling & Software, March 2008, Volume 23, Issue 3, p. 258–267.

- Ilchenko I.A. (2009) Research of primary and secondary air pollution of industrial cities and the ways to reduce it. News of Higher Educational Institutions. The North Caucasus region. Series: Natural Sciences. № 6. 79-83.

- Grigoriev, V. A., Ogorodnikov, I. A. (2001). Greening cities in the world, Russia, Siberia = Analyte. Review / State Public Scientific Technical Library of the Siberian Branch of the Russian Academy of Science. – Novosibirsk. – 143 p. – (Ecology Series. Issue 63).

- Gurova, O. S. (2000). The hydrodynamic method complex system of air purification in the construction industry enterprises working zones (theses) Materials of the 5th All-Russian Scientific and Practical Conference “New in Ecology and Health and Safety”, St. Petersburg, 2000.

- Gurova, O. S., Meshcheryakov, S. V. (2001). Methods of rational use of technological processes energy potential for ensuring ecological and production safety (theses) Materials of the International school seminar “Industrial Ecology”, Rostov-on-Don, 2001.

- Hickman, J., Hassel, D., Joumard, R., Samaras, Z., Sorenson, S. (1999). Methodology for calculating transport emissions and energy consumption Monograph

- Katzenstein, Warren, Apt, Jay (2009). Air Emissions Due To Wind And Solar Power. Environmental Science & Technology 43 (2), 253–258, DOI: 10.1021/es801437t.

- Khotko, N. I, Dmitriev, A. P. (2012). The sanitary condition of the air and human health. News of Higher Schools. Volga region. Medical science, (2).

- Mcdonald K. (2012) 11 – Air pollution in theurban atmosphere: sources and consequences. Metropolitan Sustainability, 231-259.

- Qingsong Wang, Xueliang Yuan, Jian Zhang, Ruimin Mu, Huichun Yang, Chunyuan Ma (2013) Key evaluation framework for the impacts ofurbanization on air environment – A case study. Ecological Indicators, Volume 24, 266-272.

- Read, R., Prausnits, J., Sherwood, T. (1982). Properties of gases and liquids: The handbook / Translated from English by B. I. Sokolov. – L.: Chemistry 1982. – 592 p.

- Rodionov A. I., Radikovsky, V. M., Zenkov, V. V. (1965). Determination coefficients of heat and mass transfer, referred to the phase contact surface. Processes of Chemical Technology. Hydrodynamics, heat and massoperedacha.- Moscow, 127-133.

- Soylu, S. (2007). Estimation of Turkish road transport emissions. Energy Policy, Volume 35, Issue 8, 4088–4094

- Strakhova N. A., Ovchinnikova L.Yu., Pleskachev A.B. (2002) Technical solutions on protection of air environment against the polluting substances: Monograph / Strakhova N. A., Ovchinnikova L.U., Pleskachev A.B. – Rostov on Don: Rostov State Civil Engineering University, 2002. – 332 p.

- Mishner, Y., Bespalov, V. I. (2003). Methodical bases of a choice of economic and ecologically safe technologies in gas supply systems. Industrial ecology: Materials of the International school seminar. – Rostov-on-Don: Rostov State Civil Engineering University, 2003. P. 20-22.

- Zhao, Yu., Wang, S., Duan, L., Lei, Yu., Cao P., Hao, J. (2008). Primary air pollutant emissions of coal-fired power plants in China: Current status and future prediction. Atmospheric Environment Volume 42, Issue 36, p. 8442–8452.

This work is licensed under a Creative Commons Attribution 4.0 International License.