Manuscript accepted on : 28 May 2018

Published online on: 07-06-2018

Screening For Isolation of Succinic Acid Producing Microbes

Department of Botany, Bangalore University, Bangalore - 560056, India.

Corresponding Author E-mail: hemamuniraj@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/2636

ABSTRACT: Succinic acid has emerged as one of the most competitive bio-based chemicals. Present study intended to isolate potential strains for the production of succinic acid. More than 90 isolates were obtained from various sources using anaerobic techniques. All the strains were screened for succinic acid production through bromocresol green media, thin layer chromatography and HPLC methods. 74 isolates showed colour change in bromocresol green media indicating the production of organic acids, of which 14 isolates showed succinic acid production determined by thin layer chromatography which were quantified through HPLC. The isolates which yielded succinic acid ranged from 0.24g/l (MGC) to 4.69g/l (RFC-P3).

KEYWORDS: Anaerobes; Fluid Thioglycollate; Succinic Acid; HPLC

Download this article as:| Copy the following to cite this article: Hema N, Sreenath K. P. Screening For Isolation of Succinic Acid Producing Microbes. Biosci Biotech Res Asia 2018;15(2). |

| Copy the following to cite this URL: Hema N, Sreenath K. P. Screening For Isolation of Succinic Acid Producing Microbes. Biosci Biotech Res Asia 2018;15(2). Available from: https://www.biotech-asia.org/?p=29947 |

Introduction

Succinic acid is a dicarboxylic acid produced as an intermediate of the tricarboxylic acid (TCA) cycle and also as one of the fermentation products of anaerobic metabolism.1 It is used in the manufacture of polymers, fibers, paint, inks, food additives, cosmetics, automobile bumpers, and other products. Additional markets include salts, esters and succinic acid itself. The largest demand comes from its application in the synthesis of biodegradable plastics.2

On earlier accounts, non-renewable petroleum was the sole source of deriving succinic acid which caused environmental hazards but, in the recent times the current fermentative manufacturing procedures have commenced making use of renewable feedstock for extracting this vital chemical. This biological procedure not only helps to escape the economic volatility associated with limited petroleum-based feedstock’s, also utilizes greenhouse gas carbon dioxide thus making the process more eco-friendly. Further sustainability associated in the biological pathway has led to major developments in fermentative production of succinic acid from renewable biomass (Bio-based succinic acid) in last few decades. Due to its versatile applications and increasing demand for bio-based chemicals, the market for bio-based succinic acid is expected to reach $1.1billion by 2020 by a CAGR of 45.6% (Allied Market Research Report). As a result, there is a growing interest towards discovering a more efficient and economical way for its fermentative production.

Several bacteria like Actinobacillus succinogenes, Mannheimia succiniciproducens, Anaerobiospirillum succiniciproducens, Clostridium thermosuccinogenes, E.coli Corynebacterium glutamicum, Enterococcus faecalis, Bracteroids fragilis, Enterobacter flavencens, Klebsiella pneumoniae etc and fungi such as Saccharomyces cereviseae, Yarawo lipolitica, Aspergillus niger, Penicillium simplicissium etc are reported for the production of succinic acid.3 Among them Actinobacillus succinogenes, Mannheimia succiniciproducens and Anaerobiospirillum succiniciproducens are the most intensively studied strains due to its ability to produce large amounts of succinic acids.4 Further maximum studies on succinic acid production using Actinobacillus succinogenes from various renewable biomass has been reported.5,6,7,8 The present study is to throw more light on various sources for their microbial potential and to isolate many more potent organisms for production of succinic acid.

Materials and Methods

Sample Source

Rumen fluid samples of cow, goat and sheep from municipal slaughter house in Sarjapura, Bangalore were used for inoculation. Samples also included cow dung from wide varieties of cows from a Goshala, Bangalore; dung from sheep, goat, buffalo, horse and faecal matter of poultry birds from local breeders; degrading organic waste, leachate and biogas slurry from KCDC, Bangalore; sewage sludge samples; water and soil samples from lakes in Anekal.

Culture Conditions

The samples collected from various sources were inoculated in 100ml vials containing 50ml liquid media containing (g/l): glucose 20; peptone 10; yeast extract 5.0; K2HPO4 3.0; NaCl 1.0; (NH4)2SO4 1.0; CaCl2·2H2O 0.2; MgCl2·6H2O 0.2 and Na2CO3 1.0.9 Slight modifications were made by incorporating bromocresol green (pH indicator dye) 0.02g/l in the screening media. The media pH was maintained at 6.5 to 7.0 using concentrated H2SO4. The liquid media was sterilized at 15 psi pressure and 1210C temperature for 20 minutes in bottles sealed with butyl rubber caps and aluminium crimps. N2 headspace was replaced by CO2 to make the bottle space anaerobic. Further the bottles were placed in anaerobic jar and incubated at static 370C for 24-96 hours with intermittent shaking. The jar was evacuated using vacuum pump and flushed with CO2 gas every 24 hours.

Enrichment and Isolation

The broth cultures from each vial were streaked onto solid medium in petri plates having similar composition to liquid medium further supplemented with agar 12g/l. The plates were placed in anaerobic jar and incubated at static 370C. After 24-96 hours well isolated colonies were inoculated into fresh autoclaved 100 ml vials containing 65 ml of liquid media. The bottles were maintained in anaerobic environment at static 370C for 24-96 hours with intermittent shaking. Culture isolates from all the samples were screened for succinic acid production.

Screening Techniques

Bromocresol Green Media

Bromocresol green is a dye belonging to the family triphenylmethane. It is used as a pH indicator in growth medium and titrations, wherein decrease in the pH changes the colour of the media from blue to green, later green to yellow. Organic acid production decreases the pH of the media indicated through colour change in the media. Therefore, succinic acid screening media was added with bromocresol green (0.02g/l) as indicator of organic acid production, hereafter referred as bromocresol green media. Preliminary screening of all the culture bottles for the production of organic acids was carried out by observing the colour change between 24-96 hours.

Thin Layer Chromatography

All the isolates, positive for organic acid production were resolved through thin layer chromatography for the detection of succinic acid. The samples (6ml) from the culture bottles were aseptically removed using a sterile syringe and centrifuged at 5000rpm for 20 min. The centrifuged samples (5ml) were concentrated by evaporating on hot plate to be easily detected in TLC. The evaporated samples were extracted using methanol (2ml). Silica gel 60 F254 TLC plates (Merck) were used for chromatographic developments. The samples and the standard were spotted onto the plate and resolved using solvent system comprising Di-isopropyl ether, formic acid, water (90:7:3) for 20 min.10 The plates were air dried for 30 min and heated in an oven for 10 min at 1100C. The dried TLC plates were sprayed with the chromogenic spray reagent (freshly prepared 300 mg CuSO4. 5H2O in 20 ml methanol). Faint blue spots corresponding to the standard indicated the presence of succinic acid. Samples with positive results were quantified through HPLC analysis.

HPLC Analysis

Agilent 1260 Infinity Series chromatographic system equipped with C18 column, UV-Visible detector set at 210nm was used for HPLC analysis with 0.1 sodium sulphate solution (pH adjusted to 3.0 with sulphuric acid) as mobile phase at 1ml/min flow rate and 250C column temperature. Standard was prepared by weighing 25mg of succinic acid in 50ml volumetric flask. 25ml of distilled water was added and sonicated for 10 minutes and made upto the mark with distilled water. Sample preparation was by dilution of 1ml of sample in 2ml distilled water, which was filtered through 0.2µ membrane filter. 10 µl of above prepared standard succinic acid and samples were used for the analysis.

Fluid Thioglycollate Medium

Fluid thioglycollate media is used to check the oxygen requirements of microbes. Based on the growth position in fluid thioglycollate medium, microbes can be classified in obligate aerobes, obligate anaerobes and facultative anaerobes. 29.75g of fluid thioglycollate powder was dissolved in 1000ml of distilled water. Heated to boil until the contents completely dissolved. The media was then autoclaved at 15 psi pressure and 1210C temperature for 15minutes. Freshly prepared (Freshness indicated by the presence of a pink colour in the upper one-third of the test tube) media was aseptically inoculated with the test organisms into the depths of the media by means of inoculation loop. The test tubes were incubated for 24-48 hours at static 370C.

Results and Discussion

From the various samples 90 isolates were obtained. All the isolates were screened for succnic acid production through bromocresol green media, thin layer chromatography and HPLC. Prior to succinic acid detection, organic acid production was confirmed with the help of bromocresol green media. The change in the colour of the media indicated the production of organic acids. In comparison with other methods, wherein samples obtained from the isolates were to be used to carry out preliminary tests {fluorescein test 11,12 }well diffusion method.13 to detect organic acid production, use of bromocresol green media for preliminary screening could confirm organic acid production by simple visual observation, without the need for qualitative detection tests.

|

Figure 1: Various colour changes observed in the culture bottles containing bromocresol green media due to organic acid production.

|

Among 90 isolates, excluding 16 all other isolates showed colour changes due to organic acid production. Various shades of colour changes starting from dark blue (initial colour of the media) to light blue green, dark green, olive green shades, dark mustard yellow ending with bright yellow were observed in the culture bottles between 24-96 hours (Fig 1). Isolates showing positive results in bromocresol green media were directly used for detecting succinic acid through thin layer chromatography.

|

Figure 2: HPLC analysis chromatograms of the 14 isolates positive for succinic acid production.

|

Thin layer chromatography method used could detect wide range of organic acids in minimal concentrations. Further the samples were concentrated to increase the efficiency of the method. Standard succinic acid showed blue spot with an Rf value of 0.48. All the 74 isolates showing colour change in bromocresol green media gave blue spots in thin layer chromatography confirming presence of organic acids. But, out of 90 isolates screened only 14 isolates gave faint blue spots corresponding to standard succinic acid. Further production of succinic acid from these 14 isolates was proved through HPLC. Standard Succinic acid was eluted at 11.57 minutes (RT). The chromatogram and yield of the isolates obtained through HPLC is given (Fig 2).

|

Figure 3: Culture plates of top seven high yielding isolates positive for succinic acid production

|

|

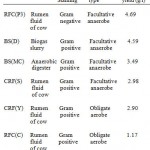

Figure 4: Gram staining images of the top seven high yielding isolates.

|

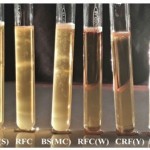

Out of the fourteen isolates producing succinic acid, top seven high yielding isolates were chosen for further study (yield >1g/l). Pure cultures of the seven isolates [RFC(P3), BS(D), BS(MC), CRF(Y), CRF(S), RFC(W), RFC(C)] were sub cultured (Figure 3). Gram staining of the above isolates were carried out (Figure 4). Growth type of the 7 isolates studied through fluid thioglycollate medium is shown in (Fig 5) and summary of the results are shown (Table 1).

|

Figure 5: Test showing growth type of the top seven high yielding isolates.

|

|

Table 1: Summary of seven high yielding isolates

|

Conclusion

Incorporation of bromocresol green dye directly in the fermentation media led to rapid preliminary screening of all the 90 isolates for the production of organic acids, making the screening procedure easier unaffecting the growth of the anaerobes. 74 isolates positive for organic acid production were screened through TLC, which yielded 14 succinic acid producing isolates i.e RFC(P3) – 4.69g/l, BS(D) – 4.59g/l, BS(MC) – 3.49g/l, CRF(S) – 2.98g/l, CRF(Y) – 2.90g/l, RFC(C) – 1.17g/l, RFC(W) – 1.02g/l, SG – 0.89g/l, SC – 0.94g/l, ASP – 0.71g/l, BS(R) – 0.51g/l, DWH – 0.49g/l, KCDC(M) – 0.33g/l and MGC – 0.24g/l. Out of 14 isolates, top 7 high yielding isolates above 1.02g/l (Table 1) have been considered as positive organisms for further studies. BS(D), BS(MC), CRF(S) are gram-positive facultative anaerobes whereas, RFC(C), RFC(W) and CRF(Y) are gram-positive obligate aerobes. Maximum yielding isolate RFC(P3) is gram- negative facultative anaerobe isolated from rumen fluid of cow.

Among the seven high yielding strains five were isolated from rumen fluid of cow. From the study it is evident that rumen fluid is the best source for isolation of succinic acid producing strains in accordance with literature, wherein most of the potent strains (Actinobacillus succinogenes, Mannheimia succiniciproducens and Anaerobiospirillum succiniciproducens) have been isolated from bovine rumen. Further studies on the high yielding isolates are being investigated for their industrial applications.

Acknowledgement

The authors gratefully acknowledge Principal, St. Joseph’s College (Autonomous), Bangalore, for providing laboratory facilities for the above work. Our heartfelt thanks to Dr. Purushothama, Professor, Department of Botany, St Joseph’s College for his guidance and support. We are also thankful to Dr. Thamizhseran, Professor, Department of Botany, for his help during the research investigation.

References

- P C Lee, S Y Lee, S H Hong, H N Chang. Isolation and characterization of a new succinic acid – producing bacterium, Mannheimia succiniciproducens MBEL55E, from bovine rumen. Appl Microbiol Biotechnol., 2002; 58: 663-668.

CrossRef - Ke-Quan Chen, Han Zhang, Ye-Lian Miao, Min Jiang, Jie-Yu Chen. Enhanced succinic acid production from sake lees hydrolysate by dilute sulphuric acid pretreatment and biotin supplementation. Journal of Sustainable Bioenergy Systems., 2012; 2: 19-25.

CrossRef - Joeri J. Beauprez, Marjan De Mey, Wim K. Soetaert. Microbial succinic acid production: Natural versus metabolic engineered producers. Process Biochemistry., 2010; 45: 1103-1114.

CrossRef - Hyohak Song and Sang Yup Lee. Production of succinic acid by bacterial fermentation. Enzyme and Microbial Technology., 2005; 39: 352-361.

- C X Wan, Y B Li, A Shahbazi, S N Xiu. Succinic acid production from cheese whey using Actinobacillus succinogenes 130 Z. Appl Biochem Biotechnol., 2008; 145: 1-3.

CrossRef - M Pilar Dorado, Sze Ki Carol Lin, Apostolis Koutinas, Chenyu Du, Ruohang Wang, Colin Webb. Cereal-based biorefinery development : Utilization of wheat milling by-products for the production of succinic acid. J Biotechnol., 2009; 143: 51-59.

CrossRef - Cho Chark Joe Leung, Anaxagoras Siu Yeung Cheung, Andrew Yan-Zhu Zhang, Koon Fung Lam. Utilization of waste bread for fermentative succinic acid production. Biochemical Engineering Journal., 2012; 65: 10-15.

CrossRef - Qiang Li, Maohua Yang, Dan Wang, Wangliang Li, Yong Wu, Yunjian Zhang, Jianmin Xing, Zhiguo Su. Efficient conversion of crop stalk wastes into succinic acid production by Actinobacillus succinogenes. Bioresour Technol., 2010; 101: 3292-3294.

CrossRef - Lata Agarwal, Jasmine Isar, Gautam K Meghwanshi, Rajendra Kumar Saxena. Influence of environmental and nutritional factors on succinic acid production and enzymes of reverse tricarboxylic acid cycle from Enterococcus flavescens. Enzyme and Microbial Technology., 2006; 40: 629-636.

CrossRef - V Gaberc-Porekar, H Soĉiĉ. New chromogenic reagent for carboxylic acids on thin layer plates. Journal of Chromatography., 1979; 178: 307-310.

CrossRef - Chandresh Thakker, Zainab Burhanpurwala, Gurdeep Rastogi, Yogesh Shouche, Dilip Ranade. Isolation and characterization of a new osmotolerant, non-virulent Klebsiella pneumoniae strain SAP for biosynthesis of succinic acid. Indian J Exp Biol., 2006; 44: 142-150.

- Lata Agarwal, Jasmine Isar, Rajendra K Saxena. Rapid screening procedures for identification of succinic acid producers. J. Biochem. Biophys. Methods., 2005; 63: 24-32.

CrossRef - M Kamran Khan, Pankaj Kishor Mishra, Umesh Kumar, Meenakshi Mishra, Taru Sharma, Vipin Permar. Production of succinic acid through anaerobic screening of related microbial strain. Global J. & Biochem., 2009; 4(1): 47-50.

- Yu-Peng Liu, Pu Zheng, Zhi-Hao Sun, Ye Ni, Jin-Jun Dong, Lei-Lei Zhu. Economical succinic acid production from cane molasses by Actinobacillus succinogenes. Bioresour Technol., 2008; 99: 1736-1742.

CrossRef - Pu Zheng, Lin Fang, Yan Xu, Jin-Jun Dong, Ye Ni, Zhi-Hao Sun. Succinic acid production from corn stover by simultaneous saccharification and fermentation using Actinobacillus succinogenes. Bioresour Technol., 2010; 101: 7889-7894.

CrossRef - Oh, In Jae, Hye Won Lee, Chul Hwan Park, Sang Yup Lee, Jinwon Lee. Succinic acid production by continuous fermentation process using Mannheimia succiniciproducens J. Microbiol. Biotechnol., 2008; 18(5): 908-912.

- Michael V. Guettler, Denise Rumler, Mahendra K. Jain. Actinobacillus succinogenes nov., a novel succinic-acid-producing strain from the bovine rumen. International Journal of systematic Bacteriology., 1999; 49: 207-216.

CrossRef - Jian Li, Xiao-Yu Zheng, Xiao-Jiang Fang, Shu-Wen Liu, Ke-Quan Chen, Min Jiang, Ping Wei, Ping-Kai Ouyang. A complete industrial system for economical succinic acid production by Actinobacillus succinogenes. Bioresource Technology., 2011; 102: 6147-6152.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.